AI na pagtataya ng imbentaryo para sa mga bodega

Ang AI na pinapagana ang pagtataya ng imbentaryo ay binabago ang operasyon ng mga bodega—binabawasan ang sobrang stock, pinipigilan ang pagkaubos ng stock, pinapababa ang gastos, at pinapahusay ang katumpakan. Mula sa mga algorithm ng machine learning hanggang sa mga nangungunang kasangkapan tulad ng SAP, Oracle, Microsoft, at Blue Yonder, tinatalakay ng artikulong ito kung paano hinuhulaan ng AI ang demand, ang mga nasusukat na benepisyo, at ang tamang mga solusyon para sa mga negosyo ng lahat ng laki—mula sa maliliit na tindahan hanggang sa mga pandaigdigang network ng distribusyon.

AI na Pinapagana ang Pagtataya ng Imbentaryo

Ang pamamahala ng imbentaryo ay isang kritikal na hamon sa operasyon ng bodega at supply chain. Ang mga tradisyunal na pamamaraan ng pagtataya—mga spreadsheet at mga pangunahing modelo ng time-series—ay nahihirapang hulihin ang mabilis na nagbabagong mga pattern ng demand ngayon, na nagreresulta sa dalawang magastos na problema: stockouts (pagkaubos ng mga produkto) at overstocking (sobra-sobrang imbentaryo na hindi nabebenta). Ang mga manwal na pamamaraan ay nakakamit lamang ng humigit-kumulang 63% na katumpakan ng imbentaryo, na nagdudulot ng nawalang benta at mataas na gastos sa pag-iimbak.

Ang mga sistemang pinapagana ng AI ay nagsusuri ng malalawak na dataset upang hulaan ang mga pangangailangan sa imbentaryo nang mas tumpak kaysa sa mga tradisyunal na pamamaraan. Ang resulta: ang mga bodega ay nakakapanatili ng mas kaunting stock habang mas natutugunan ang pangangailangan ng mga customer, na ginagawang isang competitive advantage ang imbentaryo mula sa isang sentro ng gastos.

- 1. AI na Pinapagana ang Pagtataya ng Imbentaryo

- 2. Paano Hinuhulaan ng AI ang Mga Pangangailangan sa Imbentaryo

- 3. Pangunahing Benepisyo ng AI na Pagtataya ng Imbentaryo

- 4. Mga Kasangkapan at Aplikasyon ng AI

- 5. Epekto sa Totoong Mundo at Hinaharap na Pananaw

- 6. Pangunahing Aral para sa mga Operator ng Bodega

Paano Hinuhulaan ng AI ang Mga Pangangailangan sa Imbentaryo

Gumagamit ang AI inventory forecasting ng machine learning (ML) na mga algorithm at advanced analytics upang suriin ang maraming daloy ng datos—kasaysayan ng benta, pana-panahong pagbabago, mga indikador ng ekonomiya, promosyon, panahon, at mga trend sa social media—upang matukoy ang mga kumplikadong pattern ng demand na maaaring hindi makita ng tao. Hindi tulad ng mga static na spreadsheet, ang mga modelong ito ay patuloy na natututo at nag-aadjust habang dumarating ang bagong datos, na nagpapahintulot ng real-time na pag-update ng forecast kapag nagbabago ang kalagayan ng merkado.

Halimbawa, maaaring makilala ng isang AI system ang nalalapit na regional holiday o viral na trend at hulaan ang pagtaas ng demand, na nagbibigay ng sapat na oras sa mga bodega upang mag-stock nang naaayon.

Mga Advanced na Teknik sa Pagtataya

Gumagamit ang modernong AI forecasting ng dalawang pangunahing pamamaraan:

Predictive Analytics

Demand Forecasting Algorithms

Gumagamit ang Amazon ng sopistikadong ML techniques—kabilang ang random forests at neural networks—upang pamahalaan ang milyun-milyong produkto at hindi inaasahang pagtaas ng demand. Ang kanilang AI-driven forecasting ang nagdedesisyon kung anong imbentaryo ang ilalagay sa aling bodega, na nagpapabilis ng mga Prime delivery.

— Amazon Supply Chain Operations

Mga Pagpapabuti sa Katumpakan

Ayon sa Deloitte, pinapabuti ng ML-based demand forecasting ang katumpakan ng 30–50% kumpara sa mga tradisyunal na pamamaraan. Iniulat ng McKinsey na ang mga kumpanyang gumagamit ng AI para sa supply at demand planning ay nakamit ang hanggang 50% na pagbawas sa mga error sa pagtataya.

Pinapagana rin ng AI ang dynamic segmentation—paghahati-hati ng mga produkto sa mga stable, seasonal, o sporadic na nagbebenta at inaayos ang mga patakaran sa safety stock nang naaayon. Tinitiyak nito na ang mga mabagal na gumagalaw na item ay hindi sobra ang stock habang ang mga mabilis na nagbebenta ay laging may buffer stock. Bukod dito, nagsasagawa ang AI ng what-if scenario analysis (pagsusuri ng mga posibleng pagkaantala ng supplier o biglaang pagtaas ng benta) upang matulungan ang mga planner na maghanda ng contingency stocking plans.

Pangunahing Benepisyo ng AI na Pagtataya ng Imbentaryo

Mas Mataas na Katumpakan ng Forecast

Pinapababa ng AI ang mga error sa prediksyon ng 20–50%, na nagreresulta sa mas mahusay na pagkakaroon ng produkto.

- 65% na mas kaunting nawalang benta dahil sa stockouts

- Nakamit ng Walmart ang 16% na pagbawas sa stockouts

- Pinahusay na kasiyahan ng customer

Na-optimize na Antas ng Imbentaryo

Pinananatili ang tamang dami ng stock, iniiwasan ang sobra at pinapababa ang gastos.

- 20–30% na pagbawas sa kabuuang imbentaryo

- Pinababa ng H&M ang sobrang imbentaryo ng 30%

- Mas mababang gastos sa pag-iimbak (20–25% ng halaga ng produkto taun-taon)

Mga Tipid sa Gastos sa Operasyon

Ang mga pagtaas sa kahusayan sa buong supply chain ay nagpapababa ng basura at gastos.

- 10% na pagbuti sa turnover ng imbentaryo

- 10% na pagbaba sa gastos sa logistics

- Hanggang 20% na pagbawas sa kabuuang gastos ng imbentaryo

Pinahusay na Karanasan ng Customer

Ang tuloy-tuloy na pagkakaroon ng produkto at tamang oras ng paghahatid ay nagpapataas ng kasiyahan.

- 10–15% na pagtaas sa mga score ng kasiyahan

- Nakita ng Walmart ang 2.5% na pagtaas sa kita

- 10% na pagtaas sa pagpapanatili ng customer

Mas Mabilis na Tugon at Agility

Pinapahintulutan ng real-time na pagmamanman ang mabilis na pag-aadjust sa mga pagbabago sa merkado.

- Agad na pagtuklas ng biglaang pagtaas ng demand

- Awtomatikong mga desisyon sa replenishment

- Proaktibong pag-iwas sa mga problema

Katatagan ng Supply Chain

Hinuhulaan ng AI ang mga pagkaantala at pinapahintulutan ang contingency planning.

- Pagsusuri ng mga senaryo para sa paghahanda sa panganib

- Pinababang kahinaan sa mga supply shocks

- Strategic na paghawak ng mga eksepsyon

Mga Kasangkapan at Aplikasyon ng AI

A variety of AI-powered tools and software solutions are now available to help warehouses forecast inventory needs and optimize stock levels. These applications range from enterprise-grade platforms by major tech providers to specialized solutions for mid-sized businesses. Below are some notable AI inventory forecasting tools and their key features:

SAP Integrated Business Planning (IBP)

| Developer | SAP SE |

| Supported Platforms |

|

| Global Availability | Ginagamit ng mga negosyo sa buong mundo na may suporta sa lokal na wika sa pamamagitan ng SAP ecosystem |

| Pricing Model | Bayad na solusyon na may lisensyang pang-enterprise |

Pangkalahatang-ideya

Ang SAP Integrated Business Planning (IBP) ay isang cloud-based, AI-powered na platform para sa pagpaplano ng supply chain na nakabase sa SAP HANA. Pinagsasama nito ang demand planning, inventory optimization, supply planning, sales & operations planning (S&OP), at real-time na scenario simulation sa isang pinag-isang sistema. Pinapayagan ng SAP IBP ang mga organisasyon na gumawa ng mas matalinong desisyong batay sa datos at mabilis na makibagay sa mga pagbabago sa merkado habang binabalanse ang antas ng serbisyo at working capital.

Pangunahing Mga Tampok

Gumagamit ng advanced na estadistikal na mga modelo at machine learning para sa tumpak na demand sensing at forecasting.

Ina-optimize ang mga target na safety stock sa mga lokasyon ng network upang mabawasan ang basura at mapanatili ang antas ng serbisyo.

Agad na nagpapatakbo ng mga "what-if" simulation upang suriin ang mga senaryo ng pagkagambala sa demand at supply.

Minomonitor ang performance, natutukoy ang mga exception, at nagpapasimula ng awtomatikong mga aksyon para sa pagwawasto.

Naglilink ng mga pinansyal at operational na plano sa pagitan ng mga koponan sa pananalapi, operasyon, at benta.

Pinamamahalaan ang response at supply planning gamit ang multi-level bills of material at constraint handling.

I-download o I-access

Gabay sa Pagsisimula

Tukuyin ang master data tulad ng mga produkto at lokasyon, i-configure ang mga planning area, at itakda ang mga key figure upang mabuo ang pundasyon ng iyong pagpaplano.

Gumawa ng estadistikal na baseline forecast gamit ang demand planning module, pagkatapos ay pinuhin gamit ang demand sensing para sa maikling-term na katumpakan.

I-set ang mga profile ng imbentaryo, antas ng serbisyo, at mga parameter ng multi-echelon, pagkatapos patakbuhin ang optimizer upang kalkulahin ang target na mga antas ng imbentaryo.

Gumawa ng mga view para sa response at supply planning, ilapat ang mga constraint, at isagawa ang mga planning operator upang makabuo ng mga rekomendasyong maaaring gawin.

Gumawa ng what-if analyses upang subukan ang iba't ibang senaryo ng pagkagambala sa demand o supply at ihambing ang mga resulta nang magkatabi.

I-konekta ang mga view ng IBP planning sa Microsoft Excel gamit ang SAP IBP Excel Add-In para sa mga simulation at pagsusuri ng forecast nang direkta sa Excel.

Gamitin ang web interface at naka-embed na analytics upang subaybayan ang performance ng sistema, tuklasin ang mga exception, at mag-trigger ng mga aksyon para sa pagwawasto.

Mahahalagang Pagsasaalang-alang

- Komplikadong Implementasyon: Nangangailangan ng ekspertong pagsasaayos, komprehensibong pag-setup ng master data, at pamamahala ng pagbabago sa organisasyon.

- Pagiging Flexible sa Pag-uulat: May ilang gumagamit na nagtuturo ng limitadong flexibility sa pag-uulat; madalas na nangangailangan ng pag-export sa Excel para sa mga advanced na ulat.

- Mataas na Pangangailangan sa Computational: Ang multi-echelon optimization at mga scenario simulation ay maaaring maging mabigat sa resources.

- Kritikal ang Kalidad ng Data: Mahalaga ang mataas na kalidad ng data at consistent na input sa pagpaplano; ang mahinang integrasyon ng data ay nagpapababa ng katumpakan.

Madalas na Itanong

Oo — ang SAP IBP ay native na nag-iintegrate sa SAP S/4HANA at maaari ring kumonekta sa iba pang ERP system sa pamamagitan ng data integration layers at APIs.

Oo — kasama sa SAP IBP ang Microsoft Excel add-in na nagpapahintulot sa mga planner na magpatakbo ng mga simulation, gumawa ng forecast, at mag-optimize ng imbentaryo nang direkta sa Excel.

Sinusuportahan ng IBP ang matitibay na estadistikal na modelo, time-series analysis, demand sensing, at advanced na machine learning techniques para sa tumpak na demand forecasting.

Sa pamamagitan ng paglalapat ng multi-echelon optimization, itinatakda ng IBP ang optimal na antas ng safety stock sa mga lokasyon ng network, na nagpapababa ng sobrang imbentaryo habang pinapanatili ang mga target sa serbisyo.

Wala — ang SAP IBP ay isang enterprise-grade, bayad na solusyon na karaniwang nililisensyahan ng malalaking organisasyon. Makipag-ugnayan sa SAP para sa mga detalye ng presyo at lisensya.

Oracle Demand Management Cloud

| Developer | Oracle Corporation |

| Supported Platforms |

|

| Language Support | Global — sumusuporta sa maraming wika at rehiyon. |

| Pricing Model | Bayad — enterprise cloud-licensed na solusyon. |

Pangkalahatang-ideya

Ang Oracle Demand Management Cloud ay isang cloud-native na solusyon sa pagpaplano ng supply chain na idinisenyo upang maramdaman, hulaan, at hubugin ang demand. Pinagsasama nito ang maraming signal ng demand at gumagamit ng advanced analytics upang mapabuti ang katumpakan ng forecast at i-optimize ang mga estratehiya sa imbentaryo. Pinapagana ng platform ang cross-functional na kolaborasyon at seamless na integrasyon sa mas malawak na supply chain suite ng Oracle upang i-align ang demand planning sa supply at operasyon.

Paano Ito Gumagana

Bilang bahagi ng Oracle Fusion Cloud SCM, kinukuha ng platform na ito ang makasaysayang data ng demand tulad ng mga order at shipment kasabay ng mga panlabas na stream ng demand. Gumagamit ito ng machine-learning-driven forecasting engine na may Bayesian ensemble forecasting at causal analysis upang matukoy ang mga trend, seasonality, at mga pangyayaring pang-negosyo tulad ng promosyon o pista opisyal. Ginagamit ng feature-based forecasting ang mga katangian ng produkto, lokasyon, at oras upang imodelo ang demand, na sumusuporta sa mga bagong pagpapakilala ng produkto. Maaaring magsagawa ang mga gumagamit ng what-if simulations, dynamic na segmentation ng demand, at makipagtulungan upang hubugin ang mga plano ng demand sa buong organisasyon.

Pangunahing Mga Tampok

Tumatanggap ng mga panloob at panlabas na stream ng demand kabilang ang benta, shipment, datos pang-ekonomiya, at impormasyon ng mga kaganapan.

Bayesian ensemble forecasting na may built-in na machine learning upang matukoy ang mga trend, seasonality, at anomalya.

Imodelo ang demand para sa mga bagong produkto gamit ang mga katangian ng produkto, lokasyon, at oras.

I-segment ang demand nang dinamiko gamit ang mga exception-based alert at automation ng mga patakaran sa negosyo.

Simulahin ang mga pagbabago sa demand dahil sa promosyon, presyo, at mga kaganapan upang suriin ang epekto.

Tukuyin ang mga polisiya sa imbentaryo bawat segment at bumuo ng mga plano para sa replenishment na naka-time phase.

Subaybayan ang mga KPI tulad ng MAPE, bias, at MAD na may drill-down na pagsusuri sa ugat ng problema.

Idokumento ang mga palagay, desisyon, at rebisyon nang direkta sa sistema para sa pagkakaisa ng koponan.

I-download o I-access

Pagsisimula

Mag-log in sa Oracle Fusion Cloud SCM interface upang magsimula.

I-import ang panloob at panlabas na data ng demand, kabilang ang makasaysayang shipment, order, at impormasyon sa marketing.

Pumili ng estadistikal o feature-based forecasting, piliin ang input/output measures, at itakda ang mga antas ng aggregation.

I-set up ang mga kaganapan, pista opisyal, promosyon, at pagpepresyo bilang mga causal element sa iyong forecasting model.

Gumawa ng baseline forecasts, patakbuhin ang what-if scenarios, at ihambing ang mga alternatibong plano ng demand.

Gamitin ang mga patakaran sa negosyo upang pangkatin ang mga item-location pairs ayon sa ugali at katangian ng demand.

Repasuhin ang mga pangunahing sukatan gamit ang mga dashboard upang matukoy ang mga produktong hindi maganda ang performance o mga segment.

Tukuyin ang reorder points, min-max quantities, o economic order quantities bawat segment, pagkatapos ay patakbuhin ang replenishment planning.

Idokumento ang mga palagay sa plano, desisyon, at rebisyon nang direkta sa sistema para sa transparency at pagkakaisa.

Mahahalagang Limitasyon

- Limitasyon sa pag-export: Hindi makakapag-export ang Release 24B ng mga planning table na lumalagpas sa 2 milyong cells.

- Kailangan ang kalidad ng data: Mahalaga ang mataas na kalidad ng makasaysayang demand at attribute data para sa tumpak na feature-based forecasting.

- Kompleksidad sa setup: Ang pagtukoy ng forecasting profiles, causal factors, at segmentation ay nangangailangan ng kaalaman sa pagpaplano.

- Pagdepende sa integrasyon: Pinakamainam gamitin kapag naka-integrate sa iba pang Oracle Cloud SCM modules (S&OP, Supply Planning).

Madalas Itanong

Oo — sinusuportahan nito ang feature-based forecasting gamit ang mga katangian tulad ng mga tampok ng produkto, lokasyon, at oras upang imodelo ang demand para sa mga bagong SKU na walang makasaysayang data.

Oo — maaaring magsagawa ang mga planner ng simulation, mag-annotate, at magbahagi ng mga plano ng demand habang idodokumento ang mga palagay at nakikipagtulungan sa mga koponan sa loob ng platform.

Sinusubaybayan ng Oracle Demand Management ang mga sukatan tulad ng MAPE (mean absolute percentage error), bias, at MAD. Maaaring mag-drill down ang mga planner sa mga ugat ng problema ayon sa segment para sa detalyadong pagsusuri.

Oo — maaari mong tukuyin ang polisiya sa imbentaryo bawat demand segment at bumuo ng mga time-phased na plano para sa replenishment.

Sa release 21D, sinusuportahan na ang dual units of measure (hal., timbang at bilang) sa parehong demand management at replenishment planning.

Blue Yonder Luminate Planning

| Developer | Blue Yonder, Inc. |

| Supported Platforms |

|

| Global Availability | Presensya sa buong mundo na may suporta sa maraming rehiyon at wika sa pamamagitan ng cloud platform |

| Pricing Model | Bayad — Solusyong pang-enterprise para sa pagpaplano ng supply chain |

Overview

Blue Yonder Luminate Planning ay isang AI-driven na suite para sa supply chain na nagsasama ng demand forecasting, supply planning, at inventory optimization. Sa paggamit ng real-time na datos, machine learning, at predictive analytics, tinutulungan nito ang mga organisasyon na asahan ang mga pagbabago sa demand, magsagawa ng simulation ng mga senaryo, at i-adjust ang imbentaryo nang dinamiko — na nagpapababa ng stockouts, nagpapaliit ng sobrang stock, at nagpapahusay ng katatagan ng supply chain.

How It Works

Gumagamit ang Luminate Planning ng modernong microservices architecture upang tuloy-tuloy na suriin ang mga panloob at panlabas na signal — kabilang ang makasaysayang benta, promosyon, panahon, mga kaganapan, at macroeconomic na datos. Gumagawa ito ng probabilistic forecasts gamit ang mga estadistikal na pamamaraan at AI. Sinusuportahan ng cognitive planning engine ng platform ang real-time na paglikha ng mga senaryo at mga desisyong may kamalayan sa panganib.

Isang integrated na conversational AI assistant, ang Inventory Ops Agent, ay nakakakita ng mga isyu sa kalidad ng datos at nagmumungkahi ng mga aksyong pangwasto. Kabilang sa mga karagdagang tampok ang multi-echelon inventory optimization, detalyadong segmentation ng service-level, at dynamic na network staging.

Key Features

Demand sensing gamit ang panloob at panlabas na mga signal na may machine learning-driven na mga prediksyon

Insight-driven na pagpaplano gamit ang what-if analysis at agarang simulation ng mga senaryo

Multi-echelon na pagpaplano, dynamic segmentation, at strategic network staging

Inventory Ops Agent para sa mga alerto, pag-validate ng datos, at mga guided corrective workflow

Natural language mediation sa pamamagitan ng Blue Yonder Orchestrator para sa mga insight at aksyon

Custom dashboards, planning rooms, at mobile-optimized na karanasan para sa mga remote na koponan

Download or Access

Getting Started

Isama ang mga panloob at panlabas na demand signals tulad ng mga sales order, datos ng mga kaganapan, pattern ng panahon, at mga kalendaryo ng promosyon.

Gamitin ang AI/ML engine ng Luminate upang makabuo ng baseline forecasts gamit ang estadistikal, causal, at predictive na mga teknik.

Lumikha ng what-if simulations para sa mga disruption, promosyon, o pagbabago sa demand gamit ang insight-driven planning framework.

Tukuyin ang mga patakaran sa segmentation ayon sa service level at product-channel, patakbuhin ang multi-echelon optimization, at i-stage ang imbentaryo sa buong network.

Gamitin ang Inventory Ops Agent upang matukoy ang mga anomalya, sirang elemento ng pagpaplano, at mga panganib, kasama ang mga inirekomendang aksyong pangwasto.

Gamitin ang planning rooms at dashboards upang pag-isahin ang mga koponan, subaybayan ang mga KPI, at tumugon sa mga paglihis ng forecast nang real time.

Makipag-ugnayan sa Orchestrator gamit ang keyboard o boses para sa mga insight, pagsusuri ng datos, o upang direktang mag-trigger ng mga workflow sa pagpaplano.

Important Considerations

- Mataas na kabuuang gastos sa pagmamay-ari — kinakailangan ang lisensyang pang-enterprise

- Data-intensive — kailangan ang integrasyon ng maraming panloob at panlabas na pinagkukunan ng datos

- Komplikadong implementasyon — nangangailangan ng bihasang mga resources o mga eksperto na consultant

- Patuloy na pag-tune ng modelo — kailangang muling sanayin ang mga ML model habang nagbabago ang dinamika ng negosyo

- Pagbabago sa pamamahala — kailangan ng oras ang mga koponan upang umangkop sa conversational AI at insight-driven workflows

- Hindi angkop para sa maliliit na negosyo o simpleng supply chains

Frequently Asked Questions

Sinusuportahan ng platform ang daan-daang variable kabilang ang datos ng panahon, mga promotional event, macroeconomic indicators, balita, mga uso sa social media, at mga custom na business signal upang mapabuti ang katumpakan ng forecast.

Oo — sinusuportahan nito ang multi-echelon inventory optimization at dinamiko nitong ini-stage ang imbentaryo sa lahat ng network nodes, mula sa mga distribution center hanggang sa mga retail location.

Oo — tampok ng platform ang palaging naka-on na cognitive engine na nagpapahintulot ng real-time na simulation ng mga senaryo, insight-driven na pagpaplano, at agarang paggawa ng desisyon.

Isang conversational AI assistant na patuloy na nagsusuri para sa mga isyu sa kalidad ng datos, anomalya sa plano, at mga kondisyon ng panganib, pagkatapos ay ginagabayan ang mga planner sa mga aksyong pangwasto.

Oo — maaaring ma-access ng mga planner ang mga insight, scenario briefs, at workflow sa pamamagitan ng mga mobile-optimized na dashboard para sa epektibong remote at on-the-go na pagpaplano.

Microsoft Dynamics 365 Supply Chain Insights

| Developer | Microsoft Corporation |

| Supported Platforms |

|

| Language Support | Available globally; supports multiple languages via Microsoft Dynamics 365 cloud services |

| Pricing Model | Bayad — enterprise-grade na solusyon na nangangailangan ng Dynamics 365 SCM licensing |

Pangkalahatang-ideya

Ang Microsoft Dynamics 365 Supply Chain Management (SCM) ay nag-aalok ng AI-driven na pagpaplano at forecasting ng imbentaryo gamit ang advanced predictive analytics at machine learning. Pinagsasama nito ang demand forecasting, statistical models, at real-time na data upang tulungan ang mga organisasyon na mahulaan ang demand, i-optimize ang imbentaryo, at gawing mas maayos ang replenishment sa warehouse. Sa pamamagitan ng intelligent insights, binabawasan ng Dynamics 365 ang stock-outs, pinapaliit ang sobrang imbentaryo, at pinapabuti ang tugon sa mga pagkaantala sa supply chain.

Pangunahing Kakayahan

Gumagamit ang mga module ng forecasting at demand planning ng Dynamics 365 ng Azure machine learning at built-in na mga algorithm upang makabuo ng tumpak na baseline forecasts mula sa historical data. Sinusuportahan ng sistema ang generative insights, na gumagamit ng AI upang matukoy ang seasonality, mga trend, at signal correlations, na nag-cluster ng mga item na may confidence scores upang gabayan ang mga planner.

Pinagsasama ang Microsoft Copilot para sa natural-language na interaksyon upang ipaliwanag ang mga forecast, itampok ang mga anomaly, at magsagawa ng what-if scenarios. Sinusuportahan ng solusyon ang master planning, awtomatikong pagkalkula ng reorder point, at intelligent replenishment na nakaangkop sa demand behavior, na nagbabalanse ng working capital at service levels.

Machine learning-based na demand forecasting na walang kailangan na coding at may awtomatikong tuning.

Tuklasin ang seasonality, trend clusters, at signal correlations na may confidence scoring.

Gumawa ng what-if analysis para sa mga pagbabago sa demand, disruptions, at mga polisiya sa imbentaryo.

Awtomatikong reorder points, min/max na antas ng stock, at prayoritisadong pagpaplano base sa demand.

Pinagsamang pagkomento, kasaysayan ng bersyon, at suporta sa Microsoft Teams para sa cross-team planning.

Natural-language na interaksyon upang ipaliwanag ang mga forecast, itampok ang mga anomaly, at gabayan ang mga workflow.

I-download o I-access

Pagsisimula

I-activate ang demand planning module sa Dynamics 365 SCM sa pamamagitan ng pagsasaayos ng tampok.

I-import ang kasaysayan ng benta, mga transaksyon ng imbentaryo, at mga panlabas na signal tulad ng mga promosyon at kaganapan.

Gamitin ang no-code na interface upang pumili ng mga forecast algorithm (hal., Croston, XGBoost) at itakda ang mga parameter.

Patakbuhin ang baseline statistical forecasts at suriin ang mga ito sa demand planning workspace, i-adjust kung kinakailangan.

Pumili ng time series sa planning workspace at i-click ang "Generate insights" upang ilapat ang mga AI model at tingnan ang mga cluster para sa seasonality o correlation.

Gamitin ang what-if analysis upang subukan ang mga pagbabago sa demand, mga kaganapan ng disruption, o mga polisiya sa imbentaryo.

Tukuyin ang mga reorder point, min/max na antas, at mga buffer rule base sa forecast segmentation at behavior.

Ibahagi, magkomento, at subaybayan ang kasaysayan ng bersyon sa pamamagitan ng Teams integration; aprubahan ang mga panghuling demand plan.

Patakbuhin ang intelligent replenishment at master planning upang makabuo ng mga actionable na rekomendasyon sa pagbili at paglilipat.

Mahahalagang Pagsasaalang-alang

- Mahalaga ang mataas na kalidad na historical at panlabas na signal data para sa tumpak na AI forecasting

- Maaaring mangailangan ng advanced na pagsasaayos at tuning ng espesyal na kaalaman o suporta mula sa consultant

- Nangangailangan ng Azure ML o katugmang serbisyo, na nagdaragdag ng komplikasyon at gastos sa imprastraktura

- Maaaring malaki ang gastos sa enterprise licensing; suriin nang mabuti ang ROI para sa mas maliliit na operasyon

Madalas Itanong

Ang generative insights ay isang AI-powered na tampok na nag-cluster ng demand planning time series sa mga pattern tulad ng seasonality o correlation, nag-aassign ng confidence scores, at naglalarawan nito sa natural na wika upang tulungan ang mga planner sa paggawa ng desisyon.

Oo — maaaring manu-manong i-adjust ng mga user ang mga forecast value, magpatakbo ng what-if simulations, at mag-save ng maraming bersyon para sa paghahambing at pag-apruba.

Oo — kasama sa demand planning ng Dynamics 365 ang "best-fit" forecasting algorithm (preview), tulad ng Croston's method, na partikular na idinisenyo para sa mga pattern ng intermittent demand.

Base sa forecasted demand at mga naka-configure na polisiya sa imbentaryo, ina-automate ng sistema ang reorder points, reorder quantities, at pinaprayoridad ang mga replenishment order upang i-optimize ang stock at service levels.

Oo — naka-integrate ang Microsoft Copilot upang ipaliwanag ang mga dahilan ng forecast, itampok ang mga anomaly, at tulungan ang mga workflow sa pagpaplano gamit ang natural-language na interaksyon.

ToolsGroup SO99+

| Developer | ToolsGroup B.V. |

| Platform | Web-based cloud platform |

| Global Availability | Serbisyuhan ang mga customer sa maraming bansa sa buong mundo |

| Pricing Model | Bayad — enterprise-grade na solusyon sa pagpaplano ng supply chain |

Pangkalahatang-ideya

ToolsGroup SO99+ (Service Optimizer 99+) ay isang AI-powered na platform para sa pagpaplano ng supply chain na pinagsasama ang demand forecasting, probabilistic planning, at multi-echelon inventory optimization. Pinapayagan nito ang mga koponan sa warehouse at distribusyon na balansehin ang mga target ng antas ng serbisyo sa kahusayan ng imbentaryo sa pamamagitan ng pagmomodelo ng kawalang-katiyakan sa demand, paggamit ng machine learning, at pag-optimize ng mga estratehiya sa replenishment upang mapanatili ang mataas na availability habang pinapaliit ang sobrang stock at working capital.

Paano Ito Gumagana

Nagbibigay ang SO99+ ng end-to-end na modelo ng pagpaplano na sumasaklaw sa demand, imbentaryo, at replenishment. Ang probabilistic forecasting engine nito ay nagtataya ng hanay ng mga posibleng resulta ng demand sa halip na isang tanging pagtataya, na tumutulong sa mga planner na suriin ang panganib at pagbabago-bago. Gamit ang pagmomodelo ng kawalang-katiyakan na ito, isinasagawa ng platform ang multi-echelon inventory optimization, na nagtatakda ng safety stock, reorder points, at cycle stock na nakaangkop sa bawat SKU-lokasyon batay sa nais na antas ng serbisyo.

Sinusuportahan ng platform ang dynamic sourcing at replenishment planning, na nagpapahintulot sa pag-activate ng mga backup supplier at pag-aayos ng mga target ng imbentaryo kapag nagbago ang mga kondisyon ng supply. Ang naka-embed na machine learning ay patuloy na nagpapabuti ng katumpakan ng forecast sa pamamagitan ng pag-aaral mula sa makasaysayang datos, kabilang ang mga promosyon, seasonality, at mga bagong pagpapakilala ng produkto.

Pangunahing Mga Tampok

Lumilikha ng mga hanay ng demand at mga posibilidad sa halip na mga tiyak na pagtataya, na nagmomodelo ng kawalang-katiyakan para sa pinahusay na katumpakan ng pagpaplano.

Ina-optimize ang imbentaryo sa maraming antas ng network upang matugunan ang mga layunin ng serbisyo nang may pinakamababang pamumuhunan.

Pinapayagan ang multi-sourcing, backup suppliers, mga pag-aayos sa lead-time, at constrained planning.

Nagsisimula ng iba't ibang mga polisiya sa demand, supply, at imbentaryo upang suriin ang epekto sa serbisyo at gastos.

Isinasama ang AI (hal., LightGBM) para sa forecasting ng demand, promosyon, mga bagong pagpapakilala ng produkto, at mga panlabas na signal.

Nagbibigay ng mga alerto sa hindi pagkakatugma ng forecast, seasonality clustering, at transparency sa mga driver ng modelo.

I-download o I-access

Pagsisimula

Isama ang makasaysayang benta, imbentaryo, at supply data sa SO99+. Tukuyin ang istruktura ng iyong network at itakda ang mga target ng antas ng serbisyo.

Gamitin ang probabilistic forecasting upang makabuo ng mga hanay ng demand para sa bawat SKU-lokasyon gamit ang naka-embed na mga modelo ng machine learning.

Isagawa ang multi-echelon optimization upang kalkulahin ang mga optimal na target ng imbentaryo, kabilang ang safety stock, reorder points, at cycle stock bawat node.

Itakda ang mga patakaran sa dynamic sourcing at i-configure ang what-if scenarios upang umangkop sa mga panganib at pagbabago-bago ng supply.

Gamitin ang digital twin simulation engine upang subukan ang mga plano sa imbentaryo at serbisyo sa ilalim ng iba't ibang kondisyon ng merkado.

Suriin ang mga mungkahing optimized na replenishment, gumawa ng mga pagsasaayos kung kinakailangan, at i-publish ang mga order ng replenishment.

Subaybayan ang katumpakan ng forecast, bantayan ang mga alerto sa hindi pagkakatugma, at muling sanayin ang mga modelo gamit ang bagong data upang mapabuti ang performance.

Mga Kinakailangan at Pagsasaalang-alang

- Nangangailangan ng malaking halaga ng mataas na kalidad na data: kasaysayan ng demand, lead times, BOMs, at mga limitasyon sa supply

- Kumplikasyon sa implementasyon: ang pagsasaayos ng probabilistic forecasting, ML tuning, at multi-echelon optimization ay maaaring mangailangan ng mga eksperto

- Kadalasang kailangan ang integrasyon sa ERP: SAP, Oracle, Microsoft Dynamics, o iba pang mga sistema upang ganap na magamit ang SO99+

- Ang mga output ng probabilistic at ML ay nangangailangan ng pagsasanay ng mga planner upang maunawaan ang confidence intervals at mga trade-off sa stock-service

- Hindi angkop para sa maliliit na organisasyon na may limitadong badyet dahil sa mga gastos sa lisensya at maintenance ng enterprise

Madalas Itanong

Ang SO99+ ay mahusay sa mga kumplikadong supply chain tulad ng retail, manufacturing, at distribusyon, lalo na kung saan kritikal ang intermittent demand, multi-echelon networks, at pag-optimize ng antas ng serbisyo.

Ayon sa ToolsGroup, karaniwang nakakamit ng mga customer ang 20–30% na pagbawas sa imbentaryo habang pinapahusay ang mga antas ng serbisyo.

Oo, sinusuportahan ng SO99+ ang NPI forecasting gamit ang mga modelo ng machine learning na isinasaalang-alang ang mga maagang palatandaan, katangian ng produkto, at mga signal ng merkado.

Nagbibigay ito ng dynamic sourcing at scenario planning na mga tampok upang awtomatikong i-activate ang mga backup supplier at simulahin ang epekto ng mga limitasyon sa supply.

Oo, ang automation sa pamamagitan ng probabilistic planning, machine learning, at inventory optimization ay maaaring magpababa ng workload ng mga planner ng 40–90%, ayon sa ToolsGroup.

Kinaxis RapidResponse

| Developer | Kinaxis Inc. |

| Platform | Web-based cloud-native platform |

| Global Support | Multinational deployments supported worldwide |

| Pricing Model | Paid enterprise-grade licensed solution |

Overview

Ang Kinaxis RapidResponse ay isang AI-powered concurrent planning platform na nagsasama ng supply, demand, imbentaryo, at kapasidad na datos sa loob ng isang cloud-native na kapaligiran. Dinisenyo para sa bilis at agility, nagbibigay ito ng real-time na "what-if" na mga simulation, intelligent risk sensing, at mabilis na paggawa ng desisyon. Sa paggamit ng advanced machine learning at optimization, tinutulungan ng RapidResponse ang mga organisasyon na i-optimize ang mga antas ng imbentaryo, mabilis na tumugon sa mga abala, at i-synchronize ang pagpaplano sa buong supply chain.

Core Capabilities

Pinagsasama ng RapidResponse ang maraming domain ng pagpaplano sa isang integrated platform, na nagpapahintulot ng sabay-sabay na pagbabalansi ng demand, supply, at imbentaryo. Pinagsasama ng Planning.AI engine ang heuristics, optimization, at machine learning upang maghatid ng mabilis at tumpak na mga forecast at rekomendasyon.

Kabilang sa mga tampok sa pamamahala ng imbentaryo ang:

- Single-Echelon Inventory Planning (SEIO) — pinasimpleng kontrol ng imbentaryo para sa single-tier na mga network

- Multi-Echelon Inventory Optimization (MEIO) — komprehensibong visibility at pagmomodelo ng mga patakaran sa iba't ibang antas ng network

Ang mga intelligent agents ("Maestro") ay nagbibigay ng mga insight sa natural na wika, mga alerto sa panganib, at mga preskriptibong susunod na pinakamahusay na aksyon. Pinapayagan ng concurrent planning ang dynamic na pagmomodelo ng mga senaryo, real-time na kolaborasyon, at tuloy-tuloy na pag-update ng plano habang nagbabago ang mga kondisyon.

Key Features

Pinagsasama ang heuristics, optimization, at machine learning para sa mabilis at tumpak na mga resulta ng pagpaplano.

Pinapantay ang imbentaryo sa maraming antas habang ini-optimize ang mga antas ng serbisyo at gastos.

Nagbibigay-daan sa real-time na what-if na mga simulation na may sabay-sabay na access para sa mga planner ng demand, supply, at imbentaryo.

Awtomatikong nakakakita ng mga panganib, nagpo-forecast ng mga paglihis, nagrerekomenda ng mga aksyon, at nakikipag-ugnayan gamit ang natural na wika.

Isinasama ang CO₂e emissions (Scope 3) sa mga simulation ng pagpaplano para sa pagsusuri ng epekto sa kapaligiran.

Download or Access

Getting Started

I-import ang kasaysayan ng demand, imbentaryo, lead times, BOMs, at master data sa RapidResponse.

I-set ang mga patakaran sa safety-stock at mga antas ng serbisyo para sa SEIO o MEIO-based na pagpaplano.

Gamitin ang Planning.AI engine upang makabuo ng mga optimized na plano na pinagsasama ang heuristics, optimization, at machine learning.

Gumawa ng what-if analyses sa concurrent planning workspace upang imodelo ang mga abala, pagbabago sa demand, at panganib sa supply.

Suriiin ang mga alerto mula sa mga Maestro agent, tumanggap ng mga preskriptibong rekomendasyon, at tukuyin ang mga susunod na hakbang.

Subaybayan ang mga target ng imbentaryo, aktwal, turns, at trade-offs sa pamamagitan ng komprehensibong mga dashboard.

Pag-isahin ang mga koponan gamit ang mga planning workspace at i-publish ang mga aprubadong pagbabago sa patakaran pabalik sa iyong ERP system.

Important Considerations

- Kumplikado sa pagsasaayos: ang pag-set up ng MEIO, Planning.AI, at Maestro agents ay maaaring mangailangan ng mga bihasang resources o consultant

- Enterprise licensing: malalaking gastos sa subscription at implementasyon bilang isang purpose-built na enterprise solution

- Mga system resources: ang malalaking modelo ng pagpaplano ay maaaring mangailangan ng malaking kapasidad ng in-memory architecture

- Pagbabago sa organisasyon: kailangang mag-adapt ang mga koponan sa concurrent planning workflows at AI-driven decision support

Frequently Asked Questions

Ang Planning.AI ay ang advanced analytics engine ng Kinaxis na walang putol na pinagsasama ang heuristics, optimization, at machine learning upang maghatid ng mabilis at tumpak na mga resulta ng pagpaplano sa lahat ng domain.

Oo — sinusuportahan ng RapidResponse ang multi-echelon inventory optimization (MEIO), na nagpapahintulot ng pagpaplano ng safety stock at reorder policy sa mga warehouse, transit nodes, at iba pang mga layer ng network para sa end-to-end visibility.

Ang mga Maestro agents ay mga AI-driven na katulong na awtomatikong nagmomonitor ng mga metric ng pagpaplano, nakakakita ng panganib, nagsasagawa ng mga simulation ng senaryo, at nagrerekomenda ng mga corrective action gamit ang natural na pakikipag-ugnayan sa wika.

Oo — kasama sa RapidResponse ang mga tampok sa sustainability planning, na nagpapahintulot sa mga planner na magsagawa ng simulation at optimization gamit ang CO₂e emissions (kabilang ang Scope 3) sa kanilang mga senaryo ng pagpaplano.

Oo naman — sinusuportahan ng concurrent planning architecture nito ang real-time na "what-if" na simulation ng mga senaryo, instant na recalculation ng plano, at mabilis na mga cycle ng desisyon para sa agile na pamamahala ng supply chain.

Prediko for Shopify

| Developer | Prediko Inc. |

| Supported Platforms |

|

| Language & Availability | Ingles; available sa buong mundo para sa mga mangangalakal ng Shopify |

| Pricing Model | Bayad na subscription na nagsisimula sa $49/buwan na may 14-araw na libreng pagsubok |

Pangkalahatang-ideya

Ang Prediko para sa Shopify ay isang AI-powered na solusyon para sa pagtataya ng imbentaryo at pagpaplano ng demand na iniakma para sa mga mangangalakal ng Shopify. Gumagamit ito ng machine learning at pagsusuri ng mga trend upang tumpak na mahulaan ang benta, ma-optimize ang antas ng stock, at makabuo ng mga purchase order na naka-synchronize nang real-time sa Shopify. Sa pamamagitan ng pagbawas ng stockouts at sobra-sobrang stock, pinapadali ng Prediko ang mga workflow ng imbentaryo, na tumutulong sa mga negosyo na mag-scale nang epektibo gamit ang mga desisyong replenishment na batay sa datos.

Paano Ito Gumagana

Direktang nakikipag-integrate ang Prediko sa Shopify, nag-iimport ng SKU, variant, at datos ng imbentaryo. Sinusuri ng AI engine nito ang makasaysayang benta, mga seasonal na trend, at mga rate ng paglago upang maghatid ng tumpak na mga pagtataya ng demand. Maaaring i-adjust ng mga mangangalakal ang mga forecast gamit ang top-down o bottom-up na mga pamamaraan upang tumugma sa mga layunin sa kita. Sinusuportahan ng platform ang multi-location stock balancing at pamamahala ng Bill of Materials (BOM) para sa pagpaplano sa antas ng mga bahagi. Nagbibigay ang Buying Table ng matatalinong rekomendasyon para sa reorder upang madaling makalikha at makapamahala ng mga purchase order. Tinitiyak ng mga real-time na update na ang mga forecast ay sumasalamin sa kasalukuyang imbentaryo at aktibidad ng benta.

Pangunahing Mga Tampok

Mga advanced na modelo ng machine learning na isinasaalang-alang ang seasonality, mga trend, at mga pattern ng makasaysayang benta.

Matalinong pagbuo ng purchase order sa pamamagitan ng Buying Table na may mga mungkahing optimal na dami ng order.

Subaybayan ang Bill of Materials at demand ng raw materials para sa detalyadong pagpaplano sa antas ng mga bahagi.

I-optimize ang paglilipat ng stock at imbentaryo sa iba't ibang lokasyon ng warehouse.

Mga pasadyang ulat na may flexible na mga filter at template para sa mga insight na batay sa datos.

Patuloy na pagsi-sync sa datos ng imbentaryo at benta ng Shopify para sa napapanahong mga forecast.

I-download o I-access

Pagsisimula

I-install ang Prediko mula sa Shopify App Store at bigyan ng access ang iyong mga produkto at datos ng imbentaryo.

I-import ng Prediko ang iyong katalogo sa Shopify, kabilang ang mga SKU, variant, vendor, at mga lokasyon ng imbentaryo.

Suriin ang mga forecast na ginawa ng AI at pinuhin ang mga ito gamit ang top-down o bottom-up na mga pamamaraan ng pag-edit.

Itakda ang mga threshold ng imbentaryo at mga patakaran sa reorder; nagmumungkahi ang Buying Table ng mga optimal na dami ng order.

Lumikha at pamahalaan ang mga purchase order nang direkta sa loob ng Prediko, na seamless na naka-sync sa mga supplier.

I-configure ang Bill of Materials para sa mga produkto na nangangailangan ng forecasting at pagpaplano sa antas ng mga bahagi.

Gumawa ng mga ulat sa imbentaryo at demand sa mga format na CSV o PDF para sa detalyadong pagsusuri.

Subaybayan ang real-time na datos ng imbentaryo at benta upang patuloy na i-update ang mga forecast at mga desisyon sa reorder.

Mahahalagang Pagsasaalang-alang

- Nangangailangan ng tumpak na datos mula sa Shopify (SKU mapping, makasaysayang benta) para sa maaasahang pagtataya

- Ang mga advanced na tampok tulad ng pamamahala ng BOM at multi-location balancing ay maaaring mangailangan ng paunang oras ng pagsasaayos

- Ang katumpakan ng forecast ay nakadepende sa wastong pagsasaayos ng lead-time na datos

- Kailangang may bayad na subscription; suriin ang cost-benefit para sa mas maliliit na tindahan

- Maaaring kailanganin ng manu-manong pag-aayos ang mga AI forecast sa panahon ng mabilis na pagbabago ng negosyo o mga seasonal na pagtaas

Madalas Itanong

Oo, isinama ng mga AI model ng Prediko ang seasonality at mga trend ng benta upang dynamic na i-adjust ang mga forecast batay sa makasaysayang datos at kalagayan ng merkado.

Oo, nagtataya ang Prediko ng demand para sa mga finished goods at kanilang mga bahagi gamit ang datos ng Bill of Materials para sa komprehensibong pagpaplano ng supply chain.

Ini-import ng Prediko ang mga SKU, variant, at antas ng imbentaryo nang real-time, kabilang ang mga update sa multi-location, upang matiyak na ang mga forecast ay palaging sumasalamin sa kasalukuyang stock.

Oo, nag-aalok ang Buying Table ng matatalinong rekomendasyon at nagpapahintulot ng paglikha at bulk editing ng mga purchase order nang direkta sa platform.

Oo, nagbibigay ang Prediko ng 14-araw na libreng pagsubok para sa mga bagong mangangalakal ng Shopify upang masubukan ang lahat ng mga tampok bago mag-subscribe.

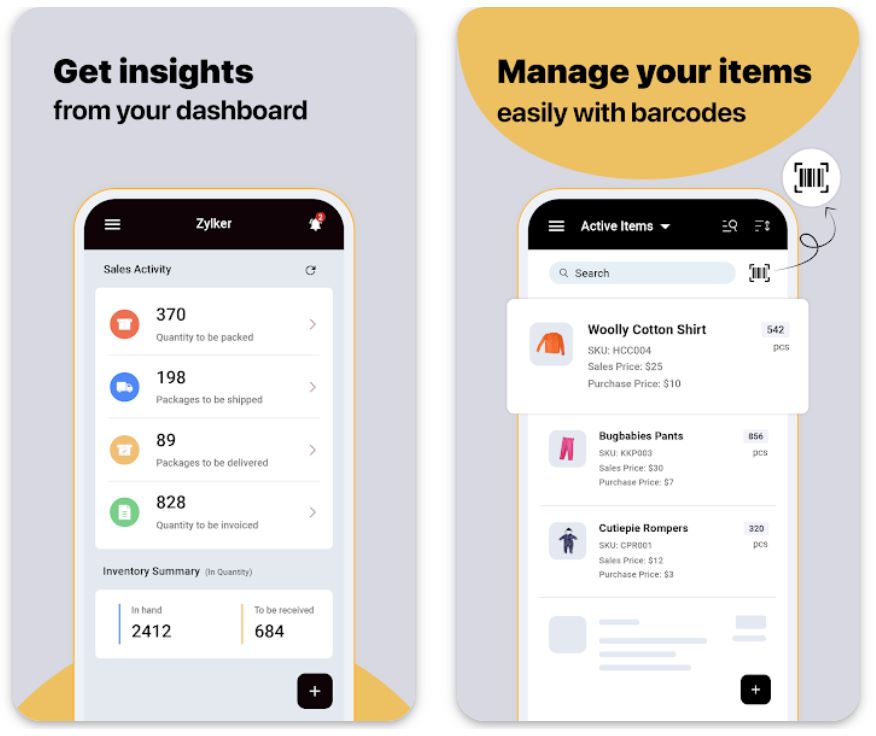

Zoho Inventory

| Developer | Zoho Corporation |

| Supported Platforms |

|

| Language Support | Ingles; available globally |

| Pricing Model | Bayad na plano na may libreng trial na available |

Pangkalahatang-ideya

Ang Zoho Inventory ay isang cloud-based na solusyon sa pamamahala ng imbentaryo na may AI-driven demand forecasting. Tinutulungan nito ang mga negosyo at bodega na mahulaan ang pangangailangan sa imbentaryo, i-optimize ang antas ng stock, at i-automate ang mga purchase order. Sa pamamagitan ng pagsusuri ng makasaysayang datos ng benta, mga pana-panahong uso, at lead times ng supplier, binabawasan nito ang kakulangan at sobra-sobrang stock, pinapabuti ang daloy ng pera, at pinapasimple ang operasyon ng bodega. Kabilang sa mga pangunahing kakayahan ang pamamahala ng maraming bodega, pag-scan ng barcode, pagsubaybay ng batch, at advanced analytics para sa komprehensibong pag-optimize ng imbentaryo.

Paano Ito Gumagana

Gumagamit ang Zoho Inventory ng AI upang suriin ang nakaraang benta, mga pana-panahong pattern, at lead times ng supplier upang makabuo ng tumpak na forecast ng demand. Maaaring magtakda ang mga gumagamit ng reorder points, safety stock levels, at mga threshold na partikular sa bawat bodega ayon sa kanilang pangangailangan. Sinusuportahan ng platform ang composite items para sa pamamahala ng mga bundle at assembly. Ang mga real-time na update sa pamamagitan ng pag-scan ng barcode, batch, at serial number tracking ay tinitiyak na ang mga forecast ay sumasalamin sa kasalukuyang imbentaryo. Ang AI-driven na pamamaraan na ito ay nagpapabawas ng sobrang stock, pumipigil sa kakulangan, at nagpapadali sa mga desisyon sa replenishment.

Pangunahing Mga Tampok

Sinusuri ang makasaysayang benta, pana-panahon, at lead times upang tumpak na mahulaan ang hinaharap na demand.

Pamahalaan ang imbentaryo sa iba't ibang lokasyon na may real-time na paglilipat ng stock at pagsasabay-sabay.

Mag-scan ng barcode, subaybayan ang mga batch, at pamahalaan ang mga serial number para sa kumpletong visibility ng imbentaryo.

Pamahalaan ang mga bundle at assembly na may automated na pagsubaybay at pag-update ng mga bahagi.

Magtakda ng safety stock at reorder thresholds na may awtomatikong pagbuo ng purchase order.

Subaybayan ang antas ng stock, katumpakan ng forecast, at performance ng imbentaryo gamit ang built-in na mga ulat.

I-download o I-access

Pagsisimula

Mag-sign up sa Zoho Inventory at i-configure ang iyong account gamit ang mga detalye ng iyong negosyo at bodega.

I-upload ang datos ng produkto, makasaysayang tala ng benta, at impormasyon ng supplier upang makabuo ng matibay na basehan para sa forecasting.

Payagan ang AI forecasting at itakda ang lead times, reorder points, at safety stock levels na angkop sa iyong negosyo.

Analisa ang mga forecast na ginawa ng AI at i-adjust ang mga ito batay sa iyong kaalaman sa merkado at pangangailangan ng negosyo.

Awtomatikong lumikha ng mga purchase order mula sa mga rekomendasyon ng forecast upang mapanatili ang tamang antas ng stock.

Gamitin ang pag-scan ng barcode, pagsubaybay ng batch, at pamamahala ng serial number para sa tumpak na imbentaryo sa real-time.

Suriin ang antas ng stock, katumpakan ng forecast, at mga sukatan ng imbentaryo gamit ang built-in na analytics at mga ulat na maaaring i-customize.

Mahahalagang Pagsasaalang-alang

- Ang biglaang pagbabago sa merkado o paglulunsad ng bagong produkto ay maaaring mangailangan ng manual na pagsasaayos ng forecast

- Ang mga update sa composite item ay maaaring hindi palaging awtomatikong maipasa sa mga dependent na item

- Ang mga advanced na senaryo ng forecasting ay maaaring mangailangan ng panlabas na analytics tools o integrasyon ng API

- Ang mga custom na ulat na lampas sa built-in na mga template ay nangangailangan ng access sa Zoho Analytics o pag-develop ng API

Madalas Itanong

Gumagamit ang Zoho Inventory ng mga AI algorithm upang suriin ang makasaysayang benta, mga pana-panahong uso, at lead times ng supplier, na bumubuo ng tumpak na forecast ng demand at nagmumungkahi ng pinakamainam na reorder points upang maiwasan ang kakulangan at sobra-sobrang stock.

Oo, sinusuportahan nito ang multi-warehouse tracking na may real-time na paglilipat ng stock at mga reorder point at safety stock levels na partikular sa bawat bodega para sa mahusay na pamamahala.

Oo, sinusuportahan ng Zoho Inventory ang composite items para sa mga bundle at assembly, bagaman ang ilang update sa dami ng mga bahagi ay maaaring mangailangan ng manual na pagsasaayos.

Ang katumpakan ng forecast ay nakadepende sa kalidad ng datos at mga setting ng lead-time. Sa maaasahang input at regular na pagsusuri, karamihan sa mga gumagamit ay nakakamit ang mataas na katumpakan na nagpapabuti sa pamamahala ng imbentaryo.

Oo, nag-aalok ang Zoho Inventory ng libreng trial na may buong access sa lahat ng tampok, kabilang ang AI-powered demand forecasting, na nagpapahintulot sa masusing pagsusuri bago bumili.

Epekto sa Totoong Mundo at Hinaharap na Pananaw

Mga Kuwento ng Tagumpay ng Nangungunang Kumpanya

Ang epekto ng AI na pagtataya ng imbentaryo ay malinaw na nakikita sa mga pangunahing operasyon ng bodega:

Walmart

H&M

Amazon

Mga Umuusbong na Teknolohiya at Mga Trend sa Hinaharap

Ang AI sa mga bodega ay nakahandang maging mas makapangyarihan pa. Kasama sa mga umuusbong na teknik ang:

- Generative AI at Agent-Based Systems: Maaaring awtomatikong makipagnegosasyon sa mga supplier kapag inaasahan ang kakulangan o dynamic na muling ruta ng imbentaryo batay sa real-time na mga signal ng demand

- Integrasyon ng IoT at Computer Vision: Mga kamera at drone na nagmomonitor ng imbentaryo sa bodega na maaaring magbigay ng live na datos sa mga modelo ng pagtataya para sa mas mahigpit na kontrol

- AI-Driven Vision Systems: Inaasahan ng Gartner na pagsapit ng 2027, kalahati ng mga kumpanya na may mga bodega ay gagamit ng AI-driven vision para sa cycle counting sa halip na manwal na pag-scan ng barcode

Pangunahing Aral para sa mga Operator ng Bodega

Ang pagpapatupad ng mga sistema ng AI ay nangangailangan ng pamumuhunan sa kalidad ng datos, pagsasanay ng mga tauhan, at pagbabago sa mga proseso. Gayunpaman, ang ROI ay maaaring malaki—nakatipid ang mga kumpanya ng daan-daang milyong dolyar sa pamamagitan ng pagbawas ng sobrang stock at pag-iwas sa markdowns gamit ang mas matalinong mga forecast. Bukod dito, pinapalaya ng AI ang mga human planner mula sa nakakapagod na pagproseso ng numero upang makapagtuon sila sa mga estratehikong desisyon at paghawak ng mga eksepsyon.

Manwal na Pagtataya

- 63% na katumpakan ng imbentaryo

- Mataas na rate ng stockout

- Gastos sa sobrang imbentaryo

- Mabagal na tugon sa mga pagbabago

AI Forecasting

- 30-50% na pagpapabuti sa katumpakan

- 65% na mas kaunting stockouts

- 20-30% na pagbawas sa imbentaryo

- Real-time na mga pag-aadjust

Sa madaling salita: Binabago ng AI na pagtataya ng imbentaryo para sa mga bodega kung paano pinaplano at pinamamahalaan ang imbentaryo. Mula sa pagpapabuti ng katumpakan ng demand forecasting at pag-automate ng replenishment hanggang sa pagpapahintulot ng proaktibong pagtugon sa mga pagkaantala sa supply chain, nagdadala ang AI ng parehong kahusayan at katatagan. Ang mga bodega na yumakap sa mga teknolohiyang ito ay nakaposisyon upang mag-operate nang may mas mataas na kahusayan, mas mababang gastos, at mas malaking kasiyahan ng customer. Habang lumalago at nagiging mas accessible ang teknolohiya, ang paggamit ng AI para sa pagpaplano ng imbentaryo ay mabilis na nagiging isang pinakamahusay na praktis sa industriya—isang bagay na hindi maaaring balewalain ng mga bodega na may pangmalas sa hinaharap.

Wala pang komento. Maging una sa magkomento!