AI-baserad lagerprognostisering för lagerlokaler

AI-driven lagerprognostisering förändrar lagerverksamheter—minskar överskott, förhindrar slut på lager, sänker kostnader och förbättrar noggrannheten. Från maskininlärningsalgoritmer till ledande verktyg som SAP, Oracle, Microsoft och Blue Yonder, förklarar denna artikel hur AI förutser efterfrågan, de mätbara fördelarna och rätt lösningar för företag i alla storlekar—från små återförsäljare till globala distributionsnätverk.

AI-baserad lagerprognostisering

Lagerhantering är en kritisk utmaning inom lager- och försörjningskedjeverksamhet. Traditionella prognosmetoder—kalkylblad och grundläggande tidsseriemodeller—har svårt att fånga dagens snabbt föränderliga efterfrågemönster, vilket leder till två kostsamma problem: slut på lager (att produkter tar slut) och överskott (för mycket osåld lager). Manuella metoder uppnår endast cirka 63 % lagerprecision, vilket resulterar i förlorad försäljning och höga lagerhållningskostnader.

AI-drivna system analyserar stora datamängder för att förutsäga framtida lagerbehov mycket mer exakt än traditionella metoder. Resultatet: lager kan hålla mindre lager samtidigt som kundernas efterfrågan bättre tillgodoses, vilket förvandlar lagret från en kostnad till en konkurrensfördel.

Hur AI förutser lagerbehov

AI-lagerprognostisering använder maskininlärning (ML)-algoritmer och avancerad analys för att analysera flera datakällor—historisk försäljning, säsongsmönster, ekonomiska indikatorer, kampanjer, väder och trender i sociala medier—för att upptäcka komplexa efterfrågemönster som människor kan missa. Till skillnad från statiska kalkylblad lär sig dessa modeller kontinuerligt och justerar sig när ny data kommer in, vilket möjliggör realtidsuppdateringar av prognoser när marknadsförhållanden förändras.

Till exempel kan ett AI-system känna igen en kommande regional helgdag eller viral trend och förutse en efterfrågetopp, vilket ger lagret tid att anpassa lagret därefter.

Avancerade prognostekniker

Modern AI-prognostisering använder två huvudsakliga metoder:

Prediktiv analys

Efterfrågeprognosalgoritmer

Amazon använder avancerade ML-tekniker—inklusive slumpmässiga skogar och neurala nätverk—för att hantera miljontals produkter och oförutsägbara efterfrågetoppar. Deras AI-drivna prognostisering avgör vilket lager som ska placera vilken inventarie, vilket möjliggör snabbare Prime-leveranser.

— Amazon Supply Chain Operations

Förbättrad noggrannhet

Enligt Deloitte förbättrar ML-baserad efterfrågeprognostisering noggrannheten med 30–50 % jämfört med traditionella metoder. McKinsey rapporterar att företag som använder AI för planering av utbud och efterfrågan uppnådde upp till 50 % minskning av prognosfel.

AI möjliggör också dynamisk segmentering—gruppering av produkter i stabila, säsongsbetonade eller sporadiska säljare och justering av säkerhetslagerregler därefter. Detta säkerställer att långsamt rörliga artiklar inte överlagras medan snabbare säljare alltid har buffertlager. Dessutom utför AI vad-om-scenarieanalys (simulering av leverantörsförseningar eller försäljningsökningar) för att hjälpa planerare att förbereda beredskapslagerplaner.

Viktiga fördelar med AI-lagerprognostisering

Högre prognosnoggrannhet

AI minskar prognosfel med 20–50 %, vilket leder till bättre produktillgänglighet.

- 65 % färre förlorade försäljningar på grund av slut på lager

- Walmart uppnådde 16 % minskning av slut på lager

- Förbättrad kundnöjdhet

Optimerade lagernivåer

Behåll rätt mängd lager, undvik överskott och sänk kostnader.

- 20–30 % minskning av totalt lager

- H&M minskade överskottslager med 30 %

- Lägre lagerhållningskostnader (20–25 % av produktvärdet årligen)

Besparingar i driftkostnader

Effektivitetsvinster i hela försörjningskedjan minskar spill och utgifter.

- 10 % förbättring av lageromsättning

- 10 % minskning av logistikkostnader

- Upp till 20 % minskning av totala lagerkostnader

Förbättrad kundupplevelse

Konsekvent produktillgänglighet och punktliga leveranser ökar nöjdheten.

- 10–15 % ökning av nöjdhetspoäng

- Walmart såg 2,5 % intäktsökning

- 10 % ökad kundlojalitet

Snabbare respons och smidighet

Realtidsövervakning möjliggör snabba anpassningar till marknadsförändringar.

- Omedelbar upptäckt av efterfrågetoppar

- Automatiserade påfyllnadsbeslut

- Proaktiv problemlösning

Motståndskraft i försörjningskedjan

AI förutser störningar och möjliggör beredskapsplanering.

- Scenarieanalys för riskberedskap

- Minskad sårbarhet för leveransstörningar

- Strategisk hantering av undantag

AI-verktyg och tillämpningar

A variety of AI-powered tools and software solutions are now available to help warehouses forecast inventory needs and optimize stock levels. These applications range from enterprise-grade platforms by major tech providers to specialized solutions for mid-sized businesses. Below are some notable AI inventory forecasting tools and their key features:

SAP Integrated Business Planning (IBP)

| Utvecklare | SAP SE |

| Stödda plattformar |

|

| Global tillgänglighet | Används av företag världen över med lokaliseringsstöd via SAP-ekosystemet |

| Prisstruktur | Betald lösning med företagslicens |

Översikt

SAP Integrated Business Planning (IBP) är en molnbaserad, AI-driven plattform för planering av försörjningskedjan byggd på SAP HANA. Den integrerar efterfrågeplanering, lageroptimering, leveransplanering, försäljnings- och verksamhetsplanering (S&OP) samt scenariosimulering i realtid i ett enhetligt system. SAP IBP gör det möjligt för organisationer att fatta smartare, datadrivna beslut och snabbt anpassa sig till marknadsförändringar samtidigt som servicenivåer och rörelsekapital balanseras.

Nyckelfunktioner

Använder avancerade statistiska modeller och maskininlärning för exakt efterfrågesensorik och prognostisering.

Optimerar säkerhetslager över nätverksplatser för att minska svinn och bibehålla servicenivåer.

Kör omedelbart ”what-if”-simuleringar för att utvärdera scenarier med störningar i efterfrågan och leverans.

Övervakar prestanda, upptäcker undantag och triggar automatiska korrigerande åtgärder.

Kopplar samman finansiella och operativa planer över ekonomi-, drift- och försäljningsteam.

Hantera respons- och leveransplanering med flernivåstycklistor och hantering av begränsningar.

Ladda ner eller få tillgång

Kom igång-guide

Definiera masterdata såsom produkter och platser, konfigurera planeringsområden och etablera nyckeltal för att bygga din planeringsgrund.

Generera statistiska basprognoser med hjälp av efterfrågeplaneringsmodulen och förfina sedan med efterfrågesensorik för kortsiktig noggrannhet.

Ställ in lagerprofiler, servicenivåer och multi-echelon-parametrar, och kör sedan optimeraren för att beräkna målade lagernivåer.

Skapa vyer för respons- och leveransplanering, tillämpa begränsningar och kör planeringsoperatörer för att generera handlingsbara rekommendationer.

Utför what-if-analyser för att testa olika scenarier med störningar i efterfrågan eller leverans och jämför resultaten sida vid sida.

Koppla IBP-planeringsvyer till Microsoft Excel via SAP IBP Excel-tillägget för simuleringar och prognosanalyser direkt i Excel.

Använd webbgränssnittet och inbäddad analys för att övervaka systemprestanda, upptäcka undantag och trigga korrigerande åtgärder.

Viktiga överväganden

- Komplex implementering: Kräver expertkonfiguration, omfattande masterdatauppsättning och förändringshantering i organisationen.

- Rapporteringsflexibilitet: Vissa användare noterar begränsad flexibilitet i rapportering; avancerade rapporter kräver ofta export till Excel.

- Beräkningskrav: Multi-echelon-optimering och scenariosimuleringar kan vara resurskrävande.

- Datakvalitet avgörande: Högkvalitativ data och konsekvent planeringsinput är avgörande; dålig dataintegration minskar noggrannheten.

Vanliga frågor

Ja — SAP IBP integreras nativt med SAP S/4HANA och kan även kopplas till andra ERP-system via dataintegrationslager och API:er.

Ja — SAP IBP inkluderar ett Microsoft Excel-tillägg som gör det möjligt för planerare att köra simuleringar, generera prognoser och optimera lager direkt i Excel.

IBP stöder robusta statistiska modeller, tidsserieanalys, efterfrågesensorik och avancerade maskininlärningstekniker för noggrann efterfrågeprognostisering.

Genom att tillämpa multi-echelon-optimering sätter IBP optimala säkerhetslagernivåer över nätverksplatser, vilket minskar överskottslager samtidigt som servicemålen bibehålls.

Nej — SAP IBP är en företagsklassad, betald lösning som vanligtvis licensieras av stora organisationer. Kontakta SAP för pris- och licensinformation.

Oracle Demand Management Cloud

| Utvecklare | Oracle Corporation |

| Stödda plattformar |

|

| Språkstöd | Globalt — stödjer flera språk och regioner. |

| Prissättningsmodell | Betald — molnlösning med företagslicens. |

Översikt

Oracle Demand Management Cloud är en molnbaserad lösning för planering av försörjningskedjan som är utformad för att känna av, förutsäga och forma efterfrågan. Den konsoliderar flera efterfrågesignaler och tillämpar avancerad analys för att förbättra prognosnoggrannheten och optimera lagerstrategier. Plattformen möjliggör tvärfunktionellt samarbete och integreras sömlöst med Oracles bredare försörjningskedjesvit för att samordna efterfrågeplanering med leverans och drift.

Så fungerar det

Som en del av Oracle Fusion Cloud SCM fångar denna plattform historisk efterfrågedata såsom order och leveranser tillsammans med externa efterfrågeströmmar. Den använder en maskininlärningsdriven prognosmotor med bayesiansk ensembleprognostisering och kausal analys för att upptäcka trender, säsongsvariationer och affärshändelser som kampanjer eller helgdagar. Funktionbaserade prognosmodeller modellerar efterfrågan med produkt-, plats- och tidsattribut och stödjer introduktion av nya produkter. Användare kan köra vad-om-simuleringar, segmentera efterfrågan dynamiskt och samarbeta för att forma efterfrågeplaner över organisationen.

Nyckelfunktioner

Tar in interna och externa efterfrågeströmmar inklusive försäljning, leveranser, ekonomiska data och händelseinformation.

Bayesiansk ensembleprognostisering med inbyggd maskininlärning för att upptäcka trender, säsongsvariationer och avvikelser.

Modellerar efterfrågan för nya produkter med produkt-, plats- och tidsattribut.

Segmenterar efterfrågan dynamiskt med undantagsbaserade varningar och automatisering av affärsregler.

Simulerar kampanj-, pris- och händelsestyrda efterfrågeförändringar för att utvärdera påverkan.

Definierar lagerpolicy per segment och genererar tidsfasade påfyllningsplaner.

Övervakar KPI:er som MAPE, bias och MAD med detaljerad rotorsaksanalys.

Dokumenterar antaganden, beslut och revisioner direkt i systemet för teamets samordning.

Ladda ner eller få åtkomst

Kom igång

Logga in i Oracle Fusion Cloud SCM-gränssnittet för att börja.

Importera interna och externa efterfrågedata, inklusive historiska leveranser, order och marknadsföringsinformation.

Välj statistisk eller funktionbaserad prognostisering, välj in- och utdata och ställ in aggregeringsnivåer.

Ställ in händelser, helgdagar, kampanjer och prissättning som kausala element i din prognosmodell.

Generera baslinjeprognoser, kör vad-om-scenarier och jämför alternativa efterfrågeplaner.

Använd affärsregler för att gruppera artikel-plats-par efter beteende och efterfrågeegenskaper.

Granska nyckeltal med hjälp av instrumentpaneler för att identifiera underpresterande produkter eller segment.

Definiera påfyllnadspunkter, min-max-kvantiteter eller ekonomiska orderkvantiteter per segment och kör sedan påfyllnadsplanering.

Dokumentera planantaganden, beslut och revisioner direkt i systemet för transparens och samordning.

Viktiga begränsningar

- Exportbegränsning: Version 24B kan inte exportera planeringstabeller som överstiger 2 miljoner celler.

- Datakvalitet krävs: Högkvalitativ historisk efterfrågan och attributdata är avgörande för exakt funktionbaserad prognostisering.

- Komplex installation: Att definiera prognosprofiler, kausala faktorer och segmentering kräver planeringsexpertis.

- Integrationsberoende: Bäst utnyttjad när den integreras med andra Oracle Cloud SCM-moduler (S&OP, Supply Planning).

Vanliga frågor

Ja — den stödjer funktionbaserad prognostisering med attribut som produktfunktioner, plats och tid för att modellera efterfrågan för nya artiklar utan historisk data.

Ja — planerare kan simulera, kommentera och dela efterfrågeplaner samtidigt som de dokumenterar antaganden och samarbetar över team inom plattformen.

Oracle Demand Management spårar mått som MAPE (medelabsolut procentuell fel), bias och MAD. Planerare kan fördjupa sig i rotorsaker per segment för detaljerad analys.

Ja — du kan definiera lagerpolicy per efterfrågesegment och generera tidsfasade påfyllnadsplaner därefter.

I version 21D stöds nu dubbla måttenheter (t.ex. vikt och antal) både i efterfrågehantering och påfyllnadsplanering.

Blue Yonder Luminate Planning

| Utvecklare | Blue Yonder, Inc. |

| Stödda plattformar |

|

| Global tillgänglighet | Global närvaro med stöd för flera regioner och språk via molnplattformen |

| Prisstruktur | Betald — Företagsnivå lösning för planering av försörjningskedjan |

Översikt

Blue Yonder Luminate Planning är en AI-driven försörjningskedjesvit som integrerar efterfrågeprognoser, försörjningsplanering och lageroptimering. Genom att utnyttja realtidsdata, maskininlärning och prediktiv analys hjälper den organisationer att förutse efterfrågeförändringar, simulera scenarier och justera lagret dynamiskt — vilket minskar brist, minimerar överskott och stärker försörjningskedjans motståndskraft.

Så fungerar det

Luminate Planning använder en modern mikrotjänstarkitektur för att kontinuerligt analysera interna och externa signaler — inklusive historisk försäljning, kampanjer, väder, evenemang och makroekonomiska data. Den genererar sannolikhetsbaserade prognoser med statistiska metoder och AI. Plattformens kognitiva planeringsmotor stödjer realtidsskapande av scenarier och riskmedvetna beslut.

En integrerad konverserande AI-assistent, Inventory Ops Agent, upptäcker datakvalitetsproblem och föreslår korrigerande åtgärder. Ytterligare funktioner inkluderar multi-echelon lageroptimering, detaljerad segmentering av servicenivåer och dynamisk nätverksplacering.

Nyckelfunktioner

Efterfrågesensorik med interna och externa signaler och maskininlärningsbaserade förutsägelser

Insiktsdriven planering med vad-händer-om-analyser och omedelbar scenariesimulering

Multi-echelon planering, dynamisk segmentering och strategisk nätverksplacering

Inventory Ops Agent för varningar, datavalidering och vägledda korrigerande arbetsflöden

Naturlig språkmedling via Blue Yonder Orchestrator för insikter och åtgärder

Anpassade instrumentpaneler, planeringsrum och mobiloptimerad upplevelse för fjärrteam

Ladda ner eller få tillgång

Kom igång

Integrera interna och externa efterfrågesignaler såsom försäljningsorder, evenemangsdata, vädermönster och kampanjkalendrar.

Använd Luminates AI/ML-motor för att generera basprognoser med statistiska, orsakssambands- och prediktiva tekniker.

Skapa vad-händer-om-simuleringar för störningar, kampanjer eller efterfrågeförskjutningar med det insiktsdrivna planeringsramverket.

Definiera segmenteringsregler efter servicenivå och produktkanal, kör multi-echelon optimering och placera lager strategiskt i nätverket.

Använd Inventory Ops Agent för att upptäcka avvikelser, trasiga planeringselement och risker, med rekommenderade korrigerande åtgärder.

Använd planeringsrum och instrumentpaneler för att samordna team, övervaka KPI:er och reagera på prognosavvikelser i realtid.

Interagera med Orchestrator via tangentbord eller röst för insikter, dataanalys eller för att direkt starta planeringsarbetsflöden.

Viktiga överväganden

- Höga totala ägandekostnader — kräver företagslicensiering

- Dataintensiv — integration av flera interna och externa datakällor behövs

- Implementeringskomplexitet — kräver skickliga resurser eller erfarna konsulter

- Löpande modelljustering — ML-modeller behöver omträning i takt med att affärsdynamiken förändras

- Förändringshantering — team behöver tid för att anpassa sig till konverserande AI och insiktsdrivna arbetsflöden

- Ej lämplig för små företag eller enkla försörjningskedjor

Vanliga frågor

Plattformen stödjer hundratals variabler inklusive väderdata, kampanjevenemang, makroekonomiska indikatorer, nyheter, trender i sociala medier och anpassade affärssignaler för att förbättra prognosnoggrannheten.

Ja — den stödjer multi-echelon lageroptimering och placerar dynamiskt lager över alla nätverksnoder, från distributionscenter till detaljhandelsplatser.

Ja — plattformen har en alltid aktiv kognitiv motor som möjliggör realtidssimulering av scenarier, insiktsdriven planering och omedelbart beslutsfattande.

En konverserande AI-assistent som kontinuerligt skannar efter datakvalitetsproblem, planavvikelser och riskförhållanden, och sedan vägleder planerare med korrigerande åtgärder.

Ja — planerare kan få tillgång till insikter, scenariebeskrivningar och arbetsflöden via mobiloptimerade instrumentpaneler för effektiv planering på distans och under resor.

Microsoft Dynamics 365 Supply Chain Insights

| Utvecklare | Microsoft Corporation |

| Stödda plattformar |

|

| Språkstöd | Tillgängligt globalt; stödjer flera språk via Microsoft Dynamics 365 molntjänster |

| Prisstruktur | Betald — företagsklassad lösning som kräver licensiering för Dynamics 365 SCM |

Översikt

Microsoft Dynamics 365 Supply Chain Management (SCM) erbjuder AI-driven planering och lagerprognostisering med avancerad prediktiv analys och maskininlärning. Det kombinerar efterfrågeprognoser, statistiska modeller och realtidsdata för att hjälpa organisationer att förutse efterfrågan, optimera lager och effektivisera påfyllning i lager. Genom att utnyttja intelligenta insikter minskar Dynamics 365 lagerbrist, minimerar överskott och förbättrar responsen vid störningar i försörjningskedjan.

Nyckelfunktioner

Dynamics 365:s prognos- och efterfrågeplaneringsmoduler använder Azure maskininlärning och inbyggda algoritmer för att skapa exakta baslinjeprognoser från historiska data. Systemet stödjer generativa insikter, där AI används för att upptäcka säsongsmönster, trender och signal-korrelationer, samt klustrar artiklar med förtroendescore för att vägleda planerare.

Integrerad Microsoft Copilot möjliggör naturliga språkinteraktioner för att förklara prognoser, lyfta fram avvikelser och simulera vad-om-scenarier. Lösningen stödjer huvudplanering, automatisk beräkning av ombeställningspunkter och intelligent påfyllning anpassad efter efterfrågebeteende, vilket balanserar rörelsekapital och servicenivåer.

Maskininlärningsbaserad efterfrågeprognostisering med kodfri uppsättning och automatisk justering.

Upptäck säsongsmönster, trendkluster och signal-korrelationer med förtroendescore.

Utför vad-om-analyser för efterfrågeförändringar, störningar och lagerpolicyer.

Automatiserade ombeställningspunkter, min/max lagernivåer och prioriterad planering baserat på efterfrågan.

Integrerad kommentering, versionshistorik och Microsoft Teams-stöd för tvärfunktionell planering.

Naturliga språkinteraktioner för att förklara prognoser, lyfta fram avvikelser och vägleda arbetsflöden.

Ladda ner eller få åtkomst

Kom igång

Aktivera efterfrågeplaneringsmodulen i Dynamics 365 SCM via funktionskonfiguration.

Importera försäljningshistorik, lagertransaktioner och externa signaler som kampanjer och evenemang.

Använd det kodfria gränssnittet för att välja prognosalgoritmer (t.ex. Croston, XGBoost) och ställa in parametrar.

Kör baslinje-statistiska prognoser och granska dem i efterfrågeplaneringsarbetsytan, justera vid behov.

Välj en tidsserie i planeringsarbetsytan och klicka på "Generera insikter" för att tillämpa AI-modeller och visa kluster för säsongsmönster eller korrelation.

Använd vad-om-analys för att testa efterfrågeförändringar, störningsevent eller lagerpolicyer.

Definiera ombeställningspunkter, min/max-nivåer och buffertregler baserat på prognossegmentering och beteende.

Dela, kommentera och spåra versionshistorik via Teams-integration; godkänn slutgiltiga efterfrågeplaner.

Kör intelligent påfyllning och huvudplanering för att generera handlingsbara inköps- och överföringsrekommendationer.

Viktiga överväganden

- Högkvalitativ historisk och extern signaldatal är avgörande för exakt AI-prognostisering

- Avancerad konfiguration och justering kan kräva specialiserad expertis eller konsultstöd

- Kräver Azure ML eller kompatibla tjänster, vilket ökar infrastrukturens komplexitet och kostnad

- Företagslicenskostnader kan vara betydande; utvärdera ROI noggrant för mindre verksamheter

Vanliga frågor

Generativa insikter är en AI-driven funktion som klustrar efterfrågeplaneringens tidsserier i mönster som säsongsmönster eller korrelation, tilldelar förtroendescore och beskriver dem i naturligt språk för att hjälpa planerare i beslutsfattandet.

Ja — användare kan manuellt justera prognosvärden, köra vad-om-simuleringar och spara flera versioner för jämförelse och godkännande.

Ja — Dynamics 365:s efterfrågeplanering inkluderar en "bäst-passande" prognosalgoritm (förhandsgranskning), såsom Crostons metod, speciellt utformad för intermittenta efterfrågemönster.

Baserat på prognostiserad efterfrågan och konfigurerade lagerpolicyer automatiserar systemet ombeställningspunkter, ombeställningskvantiteter och prioriterar påfyllningsorder för att optimera lager och servicenivåer.

Ja — Microsoft Copilot är integrerat för att förklara prognosresonemang, lyfta fram avvikelser och assistera planeringsarbetsflöden via naturlig språkinteraktion.

ToolsGroup SO99+

| Utvecklare | ToolsGroup B.V. |

| Plattform | Webbaserad molnplattform |

| Global tillgänglighet | Betjänar kunder i flera länder världen över |

| Prisstruktur | Betald — företagsklassad lösning för planering av försörjningskedjan |

Översikt

ToolsGroup SO99+ (Service Optimizer 99+) är en AI-driven plattform för planering av försörjningskedjan som integrerar efterfrågeprognoser, probabilistisk planering och multi-nivå lageroptimering. Den gör det möjligt för lager- och distributionsgrupper att balansera servicenivåmål med lager-effektivitet genom att modellera efterfrågeosäkerhet, tillämpa maskininlärning och optimera påfyllnadsstrategier för att upprätthålla hög tillgänglighet samtidigt som överskottslager och bundet kapital minimeras.

Så fungerar det

SO99+ erbjuder en helhetsmodell för planering som täcker efterfrågan, lager och påfyllning. Dess probabilistiska prognosmotor förutspår ett spann av efterfrågeutfall istället för en enda uppskattning, vilket hjälper planerare att bedöma risk och variation. Med denna osäkerhetsmodellering utför plattformen multi-nivå lageroptimering, där säkerhetslager, beställningspunkter och cykellager anpassas för varje SKU-plats baserat på önskade servicenivåer.

Plattformen stödjer dynamisk inköps- och påfyllnadsplanering, vilket möjliggör aktivering av reservleverantörer och justering av lagermål när leveransförhållanden förändras. Inbyggd maskininlärning förbättrar kontinuerligt prognosnoggrannheten genom att lära från historiska data, inklusive kampanjer, säsongsvariationer och nya produktlanseringar.

Nyckelfunktioner

Genererar efterfrågespann och sannolikheter istället för fasta uppskattningar, vilket modellerar osäkerhet för förbättrad planeringsprecision.

Optimerar lager över flera nätverksnivåer för att uppnå servicemål med minimal kapitalbindning.

Möjliggör multisourcing, reservleverantörer, justering av ledtider och begränsad planering.

Simulerar olika efterfråge-, leverans- och lagerpolicys för att utvärdera påverkan på service och kostnader.

Inkluderar AI (t.ex. LightGBM) för prognoser av efterfrågan, kampanjer, nya produktlanseringar och externa signaler.

Erbjuder varningar vid prognosavvikelser, säsongsklustring och insyn i modellens drivkrafter.

Ladda ner eller få tillgång

Kom igång

Integrera historisk försäljnings-, lager- och leveransdata med SO99+. Definiera din nätverksstruktur och sätt servicenivåmål.

Använd probabilistisk prognostisering för att generera efterfrågespann för varje SKU-plats med inbyggda maskininlärningsmodeller.

Utför multi-nivå optimering för att beräkna optimala lagermål, inklusive säkerhetslager, beställningspunkter och cykellager per nod.

Sätt regler för dynamisk inköp och konfigurera what-if scenarier för att anpassa dig till leveransrisker och variationer.

Använd den digitala tvillingsimuleringen för att testa lager- och serviceplaner under olika marknadsförhållanden.

Granska optimerade påfyllnadsförslag, gör justeringar vid behov och publicera påfyllnadsorder.

Övervaka prognosnoggrannhet, följ upp varningar vid avvikelser och träna om modeller med ny data för att förbättra prestanda.

Krav & överväganden

- Kräver omfattande, högkvalitativ data: efterfrågehistorik, ledtider, stycklistor och leveransbegränsningar

- Implementeringskomplexitet: konfiguration av probabilistisk prognostisering, ML-justering och multi-nivå optimering kan kräva expertresurser

- ERP-integration ofta nödvändig: SAP, Oracle, Microsoft Dynamics eller andra system för att fullt ut utnyttja SO99+

- Probabilistiska och ML-resultat kräver utbildning för planerare att tolka konfidensintervall och lager-serviceavvägningar

- Ej lämplig för små organisationer med begränsade budgetar på grund av företagslicensiering och underhållskostnader

Vanliga frågor

SO99+ är särskilt lämpad för komplexa försörjningskedjor som detaljhandel, tillverkning och distribution, särskilt där intermittent efterfrågan, multi-nivå nätverk och optimering av servicenivåer är avgörande.

ToolsGroup rapporterar att kunder vanligtvis uppnår 20–30 % lagerreduktioner samtidigt som servicenivåerna förbättras.

Ja, SO99+ stödjer NPI-prognostisering med maskininlärningsmodeller som inkluderar tidiga indikatorer, produktattribut och marknadssignaler.

Den erbjuder funktioner för dynamisk inköp och scenarieplanering för att automatiskt aktivera reservleverantörer och simulera effekter av leveransbegränsningar.

Ja, automatisering genom probabilistisk planering, maskininlärning och lageroptimering kan enligt ToolsGroup minska planerarnas arbetsbelastning med 40–90 %.

Kinaxis RapidResponse

| Utvecklare | Kinaxis Inc. |

| Plattform | Webbaserad molnbaserad plattform |

| Global support | Multinationella implementationer stöds globalt |

| Prisstruktur | Betald företagslösning med licensiering |

Översikt

Kinaxis RapidResponse är en AI-driven plattform för samtidig planering som integrerar data om leverans, efterfrågan, lager och kapacitet i en enda molnbaserad miljö. Byggd för snabbhet och smidighet möjliggör den realtids-"vad händer om"-simuleringar, intelligent riskupptäckt och snabb beslutsfattning. Genom att använda avancerad maskininlärning och optimering hjälper RapidResponse organisationer att optimera lagernivåer, snabbt reagera på störningar och synkronisera planeringen över hela försörjningskedjan.

Kärnfunktioner

RapidResponse konsoliderar flera planeringsdomäner på en integrerad plattform, vilket möjliggör samtidig balansering av efterfrågan, tillgång och lager. Planning.AI-motorn kombinerar heuristik, optimering och maskininlärning för att leverera snabba och exakta prognoser och rekommendationer.

Funktioner för lagerhantering inkluderar:

- Single-Echelon Inventory Planning (SEIO) — effektiv lagerkontroll för nätverk med en nivå

- Multi-Echelon Inventory Optimization (MEIO) — omfattande insyn och policyhantering över flera nätverksnivåer

Intelligenta agenter ("Maestro") ger insikter på naturligt språk, riskvarningar och föreskrivande rekommendationer för nästa bästa åtgärder. Samtidig planering möjliggör dynamisk scenariomodellering, realtidssamarbete och kontinuerliga planuppdateringar när förutsättningarna förändras.

Viktiga funktioner

Kombinerar heuristik, optimering och maskininlärning för snabba och precisa planeringsresultat.

Balanserar lager över flera nivåer samtidigt som servicenivåer och kostnader optimeras.

Möjliggör realtidssimuleringar av vad-händer-om med samtidig åtkomst för planerare av efterfrågan, tillgång och lager.

Upptäcker risker autonomt, förutser avvikelser, rekommenderar åtgärder och interagerar via naturligt språk.

Inkluderar CO₂e-utsläpp (Scope 3) i planeringssimuleringar för miljöpåverkansanalys.

Ladda ner eller få tillgång

Kom igång

Importera historisk efterfrågan, lager, ledtider, stycklistor och masterdata till RapidResponse.

Ställ in säkerhetslagerpolicyer och servicenivåer för SEIO- eller MEIO-baserad planering.

Använd Planning.AI-motorn för att generera optimerade planer som kombinerar heuristik, optimering och maskininlärning.

Utför vad-händer-om-analyser i arbetsytan för samtidig planering för att modellera störningar, efterfrågeförändringar och leveransrisker.

Analysera varningar från Maestro-agenter, ta emot föreskrivande rekommendationer och bestäm nästa steg.

Följ lagermål, faktiska värden, omsättningar och avvägningar via omfattande instrumentpaneler.

Samordna team med hjälp av planeringsarbetsytor och publicera godkända policyändringar tillbaka till ditt ERP-system.

Viktiga överväganden

- Konfigurationskomplexitet: uppsättning av MEIO, Planning.AI och Maestro-agenter kan kräva kompetenta resurser eller konsulter

- Företagslicensiering: betydande prenumerations- och implementeringskostnader som en specialbyggd företagslösning

- Systemresurser: stora planeringsmodeller kan kräva omfattande kapacitet i minnesarkitektur

- Organisatorisk förändring: team måste anpassa sig till arbetsflöden för samtidig planering och AI-baserat beslutsstöd

Vanliga frågor

Planning.AI är Kinaxis avancerade analysmotor som sömlöst kombinerar heuristik, optimering och maskininlärning för att leverera snabba och exakta planeringsresultat över alla domäner.

Ja — RapidResponse stödjer multi-echelon lageroptimering (MEIO), vilket möjliggör planering av säkerhetslager och omläggningspolicyer över lager, transitpunkter och andra nätverkslager för fullständig insyn.

Maestro-agenter är AI-drivna assistenter som autonomt övervakar planeringsmått, upptäcker risker, simulerar scenarier och rekommenderar korrigerande åtgärder med hjälp av naturligt språk.

Ja — RapidResponse inkluderar funktioner för hållbarhetsplanering som gör det möjligt för planerare att simulera och optimera med CO₂e-utsläpp (inklusive Scope 3) i sina planeringsscenarier.

Absolut — dess arkitektur för samtidig planering stödjer realtidssimulering av "vad händer om"-scenarier, omedelbar omräkning av planer och snabba beslutscykler för agil försörjningskedjehantering.

Prediko for Shopify

| Utvecklare | Prediko Inc. |

| Stödda plattformar |

|

| Språk & Tillgänglighet | Engelska; tillgängligt globalt för Shopify-handlare |

| Prissättningsmodell | Betald prenumeration från 49 USD/månad med en 14-dagars gratis provperiod |

Översikt

Prediko för Shopify är en AI-driven lösning för lagerprognoser och efterfrågeplanering anpassad för Shopify-handlare. Den använder maskininlärning och trendanalys för att exakt förutsäga försäljning, optimera lagernivåer och generera inköpsorder som synkroniseras i realtid med Shopify. Genom att minska slut på lager och överlager effektiviserar Prediko lagerhanteringen och hjälper företag att växa effektivt med datadrivna påfyllningsbeslut.

Så fungerar det

Prediko integreras sömlöst med Shopify och importerar SKU-, variant- och lagerdata. Dess AI-motor analyserar historisk försäljning, säsongstrender och tillväxttakter för att leverera precisa efterfrågeprognoser. Handlare kan justera prognoser med top-down- eller bottom-up-metoder för att matcha intäktsmål. Plattformen stödjer lagerbalansering på flera platser och hantering av stycklistor (BOM) för planering på komponentnivå. Buying Table erbjuder smarta påfyllningsrekommendationer för enkel skapande och hantering av inköpsorder. Realtidsuppdateringar säkerställer att prognoser alltid speglar aktuellt lager och försäljningsaktivitet.

Viktiga funktioner

Avancerade maskininlärningsmodeller som tar hänsyn till säsongsvariationer, trender och historiska försäljningsmönster.

Intelligent generering av inköpsorder via Buying Table med förslag på optimal orderkvantitet.

Följ stycklistor och efterfrågan på råmaterial för detaljerad planering på komponentnivå.

Optimera lageröverföringar och lagerhantering över flera lagerplatser.

Anpassningsbara rapporter med flexibla filter och mallar för datadrivna insikter.

Kontinuerlig synkronisering med Shopify-lager- och försäljningsdata för uppdaterade prognoser.

Ladda ner eller få tillgång

Kom igång

Installera Prediko från Shopify App Store och ge åtkomst till dina produkter och lagerdata.

Prediko importerar din Shopify-katalog, inklusive SKU:er, varianter, leverantörer och lagerplatser.

Granska AI-genererade prognoser och förfina dem med top-down- eller bottom-up-redigering.

Ställ in lagernivågränser och påfyllningsregler; Buying Table föreslår optimal orderkvantitet.

Skapa och hantera inköpsorder direkt i Prediko med sömlös synkronisering till leverantörer.

Konfigurera stycklistor för produkter som kräver komponentprognoser och planering.

Generera lager- och efterfrågerapporter i CSV- eller PDF-format för detaljerad analys.

Följ realtidsdata för lager och försäljning för att kontinuerligt uppdatera prognoser och påfyllningsbeslut.

Viktiga överväganden

- Kräver korrekt Shopify-data (SKU-kartläggning, historisk försäljning) för tillförlitliga prognoser

- Avancerade funktioner som BOM-hantering och lagerbalansering på flera platser kan kräva initial installationstid

- Prognosnoggrannhet beror på korrekt konfiguration av ledtider

- Betald prenumeration krävs; utvärdera kostnad kontra nytta för mindre butiker

- AI-prognoser kan behöva manuell justering vid snabba affärsförändringar eller säsongstoppar

Vanliga frågor

Ja, Predikos AI-modeller inkluderar säsongsvariationer och försäljningstrender för att dynamiskt justera prognoser baserat på historisk data och marknadsförhållanden.

Ja, Prediko prognostiserar efterfrågan för färdiga varor och deras komponenter med hjälp av stycklistedata för omfattande leverantörskedjeplanering.

Prediko importerar SKU:er, varianter och lagernivåer i realtid, inklusive uppdateringar för flera lagerplatser, vilket säkerställer att prognoser alltid speglar aktuellt lager.

Ja, Buying Table erbjuder smarta rekommendationer och möjliggör skapande och massredigering av inköpsorder direkt i plattformen.

Ja, Prediko erbjuder en 14-dagars gratis provperiod för nya Shopify-handlare att utforska alla funktioner innan prenumeration.

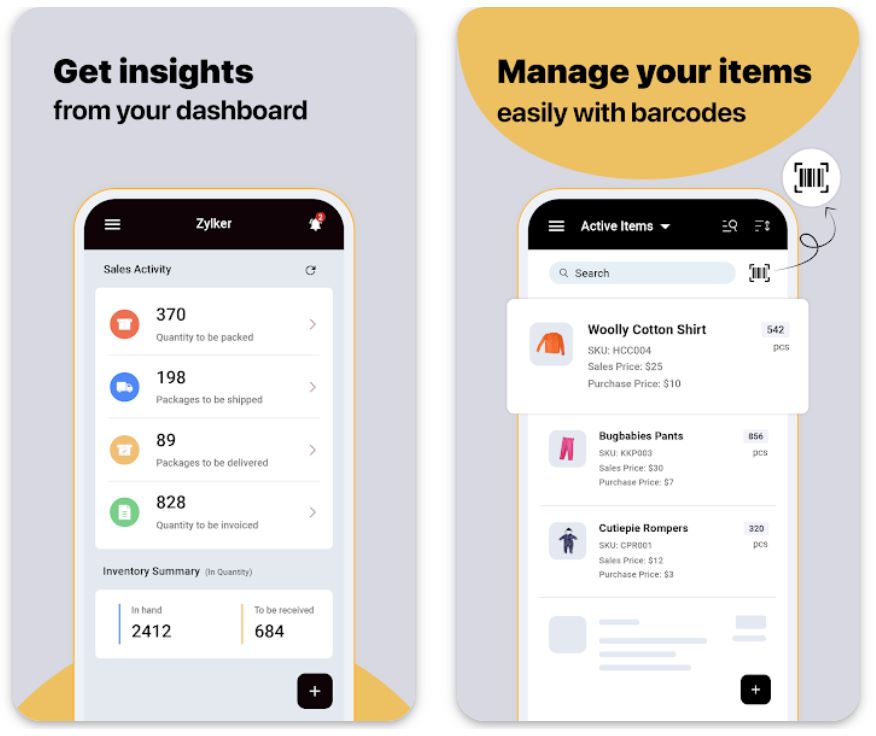

Zoho Inventory

| Utvecklare | Zoho Corporation |

| Stödda plattformar |

|

| Språkstöd | Engelska; tillgängligt globalt |

| Prissättningsmodell | Betalda planer med gratis provperiod tillgänglig |

Översikt

Zoho Inventory är en molnbaserad lagerhanteringslösning med AI-driven efterfrågeprognostisering. Den hjälper företag och lager att förutsäga lagerbehov, optimera lagernivåer och automatisera inköpsorder. Genom att analysera historisk försäljningsdata, säsongstrender och leverantörers ledtider minimerar den lagerbrist och överlager, förbättrar kassaflödet och effektiviserar lagerhanteringen. Viktiga funktioner inkluderar hantering av flera lager, streckkodsskanning, batchspårning och avancerad analys för omfattande lageroptimering.

Så fungerar det

Zoho Inventory använder AI för att analysera tidigare försäljning, säsongsmönster och leverantörers ledtider för att generera exakta efterfrågeprognoser. Användare kan ställa in omläggningspunkter, säkerhetslager och lagerplats-specifika tröskelvärden anpassade efter deras behov. Plattformen stödjer sammansatta artiklar för hantering av paket och sammanställningar. Realtidsuppdateringar via streckkodsskanning, batch- och serienummeruppföljning säkerställer att prognoserna speglar aktuellt lager. Detta AI-drivna tillvägagångssätt minskar överskott, förhindrar lagerbrist och förenklar påfyllnadsbeslut.

Nyckelfunktioner

Analyserar historisk försäljning, säsongsvariationer och ledtider för att noggrant förutsäga framtida efterfrågan.

Hantera lager över flera platser med realtidsöverföringar och synkronisering av lagerstatus.

Skanna streckkoder, spåra batcher och hantera serienummer för fullständig lageröversikt.

Hantera paket och sammanställningar med automatiserad komponentspårning och uppdateringar.

Ställ in säkerhetslager och omläggningströsklar med automatisk generering av inköpsorder.

Övervaka lagernivåer, prognosnoggrannhet och lagerprestanda med inbyggda rapporter.

Ladda ner eller få tillgång

Kom igång

Registrera dig för Zoho Inventory och konfigurera ditt konto med dina företags- och lageruppgifter.

Ladda upp produktdata, historiska försäljningsregister och leverantörsinformation för att bygga en stabil prognosgrund.

Aktivera AI-prognostisering och ställ in ledtider, omläggningspunkter och säkerhetslager anpassade efter ditt företag.

Analysera AI-genererade prognoser och justera dem baserat på dina marknadsinsikter och affärsbehov.

Skapa automatiskt inköpsorder från prognosrekommendationer för att bibehålla optimala lagernivåer.

Använd streckkodsskanning, batchspårning och hantering av serienummer för realtidsnoggrannhet i lagret.

Granska lagernivåer, prognosnoggrannhet och lagerstatistik med inbyggd analys och anpassningsbara rapporter.

Viktiga överväganden

- Plötsliga marknadsförändringar eller nya produktlanseringar kan kräva manuella justeringar av prognoser

- Uppdateringar av sammansatta artiklar kanske inte alltid sprids automatiskt till beroende artiklar

- Avancerade prognosscenarier kan behöva externa analysverktyg eller API-integration

- Anpassade rapporter utöver inbyggda mallar kräver tillgång till Zoho Analytics eller API-utveckling

Vanliga frågor

Zoho Inventory använder AI-algoritmer för att analysera historisk försäljning, säsongstrender och leverantörers ledtider, vilket genererar exakta efterfrågeprognoser och föreslår optimala omläggningspunkter för att undvika lagerbrist och överlager.

Ja, det stödjer spårning av flera lager med realtidsöverföringar och lagerplats-specifika omläggningspunkter och säkerhetslager för effektiv hantering.

Ja, Zoho Inventory stödjer sammansatta artiklar för paket och sammanställningar, även om vissa uppdateringar av komponentkvantiteter kan kräva manuella justeringar.

Prognosens noggrannhet beror på datakvalitet och ledtidsinställningar. Med pålitliga indata och regelbunden granskning uppnår de flesta användare hög noggrannhet som förbättrar lagerhanteringen.

Ja, Zoho Inventory erbjuder en gratis provperiod med full tillgång till alla funktioner, inklusive AI-driven efterfrågeprognostisering, vilket möjliggör en grundlig utvärdering före köp.

Verklig påverkan och framtidsutsikter

Framgångshistorier från ledande företag

Effekten av AI-lagerprognostisering är redan tydlig i stora lagerverksamheter:

Walmart

H&M

Amazon

Framväxande teknologier och framtida trender

AI i lager är på väg att bli ännu mer kapabelt. Framväxande tekniker inkluderar:

- Generativ AI och agentbaserade system: Kan automatiskt förhandla med leverantörer vid förväntade brister eller dynamiskt omdirigera lager baserat på realtidsdata

- IoT och datorseendeintegration: Kameror och drönare som övervakar lager kan mata live-data till prognosmodeller för tätare kontroll

- AI-drivna visionssystem: Gartner förutspår att hälften av företagen med lager kommer att använda AI-drivna visionssystem för cykelräkning istället för manuella streckkodsskanningar år 2027

Viktiga slutsatser för lageroperatörer

Implementering av AI-system kräver investeringar i datakvalitet, personalutbildning och processförändringar. Men avkastningen kan vara betydande—företag har sparat hundratals miljoner dollar genom att minska överskott och undvika prissänkningar tack vare smartare prognoser. Dessutom frigör AI mänskliga planerare från tråkigt sifferarbete så att de kan fokusera på strategiska beslut och hantering av undantag.

Manuell prognostisering

- 63 % lagerprecision

- Höga nivåer av slut på lager

- Kostnader för överskottslager

- Långsam respons på förändringar

AI-prognostisering

- 30–50 % förbättrad noggrannhet

- 65 % färre slut på lager

- 20–30 % lagerreduktion

- Realtidsjusteringar

Sammanfattningsvis: AI-lagerprognostisering för lagerlokaler förändrar hur lager planeras och hanteras. Från förbättrad efterfrågeprognos och automatiserad påfyllning till möjliggörande av proaktiva svar på störningar i försörjningskedjan, ger AI både effektivitet och motståndskraft. Lager som anammar dessa teknologier positionerar sig för att arbeta med högre effektivitet, lägre kostnader och större kundnöjdhet. När tekniken mognar och blir mer tillgänglig går användningen av AI för lagerplanering snabbt från att vara ett toppmodernt alternativ till en branschstandard—en som inget framåtblickande lager kan ignorera.

Inga kommentarer än. Var först med att kommentera!