AI in Manufacturing and Industry

Artificial Intelligence (AI) is transforming manufacturing and industry by optimizing production, reducing costs, and improving efficiency. From predictive maintenance and quality control to supply chain automation, AI is driving innovation and creating smarter factories.

Artificial intelligence is rapidly transforming manufacturing by boosting efficiency, improving quality, and enabling smarter production. Industry surveys show that around 90% of manufacturers are already using some form of AI, though many feel they still lag behind competitors.

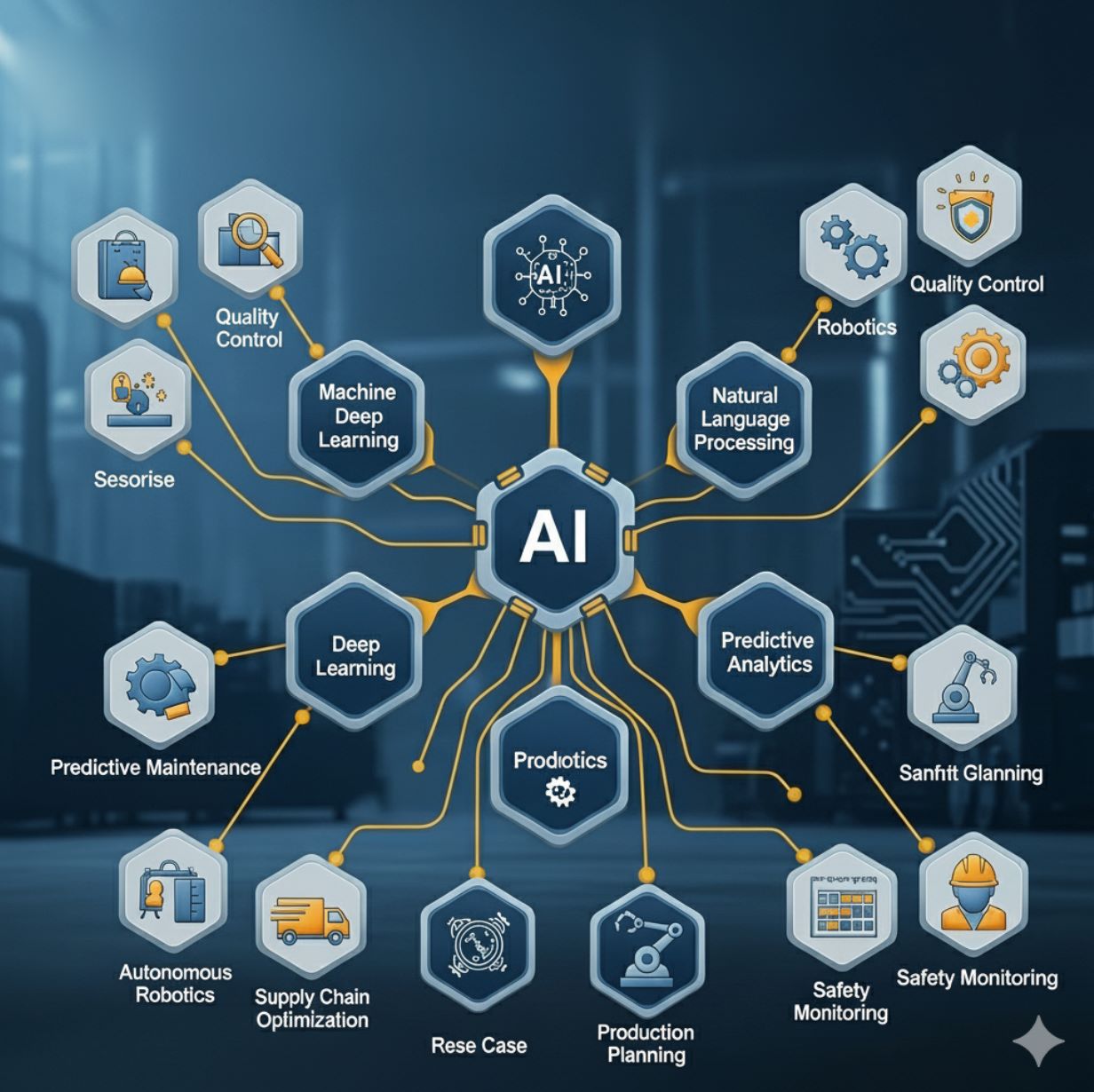

Key AI Technologies and Use Cases

Manufacturers are applying a range of AI techniques to automate and optimize production across multiple operational areas:

Predictive Maintenance

AI algorithms analyze sensor data from machines to forecast equipment failures before they happen. By using machine learning models and digital twins, companies can schedule maintenance proactively.

- Cuts downtime and repair costs significantly

- Major automakers predict faults in assembly-line robots

- Schedules repairs during non-peak hours

Computer Vision Quality Control

Advanced vision systems inspect products in real time to catch defects far faster and more accurately than human inspectors.

- Cameras and AI compare parts against ideal specifications

- Flags anomalies immediately

- Reduces waste and rejects without slowing production

Collaborative Robots (Cobots)

A new generation of AI-powered robots can work safely alongside humans on the factory floor, handling repetitive, precise, or heavy tasks.

- Electronics manufacturers use cobots for tiny component placement

- Humans focus on monitoring and creative problem-solving

- Boosts productivity and ergonomics

Digital Twins and IoT

Virtual replicas of machinery or entire plants enable simulations and optimizations without interrupting actual production lines.

- Real-time IoT sensor data feeds the twin

- Engineers model "what-if" scenarios

- Optimize layouts and predict outcomes

Generative Design and AI-Driven Product Development

By training on data about materials, constraints and past designs, generative AI tools can create optimized parts and prototypes automatically. Aerospace and automotive firms are already using this for lightweight, strong components.

- Automatically generates optimized component designs

- Enables mass customization by quickly adapting to customer preferences

- Reduces time-to-market without halting production

These "smart factory" systems use connected devices and data analytics so that production can self-adjust in real time. The result is a highly flexible, efficient plant where AI constantly monitors operations, maximizes throughput, and reduces waste without human intervention.

— IBM, Smart Manufacturing Research

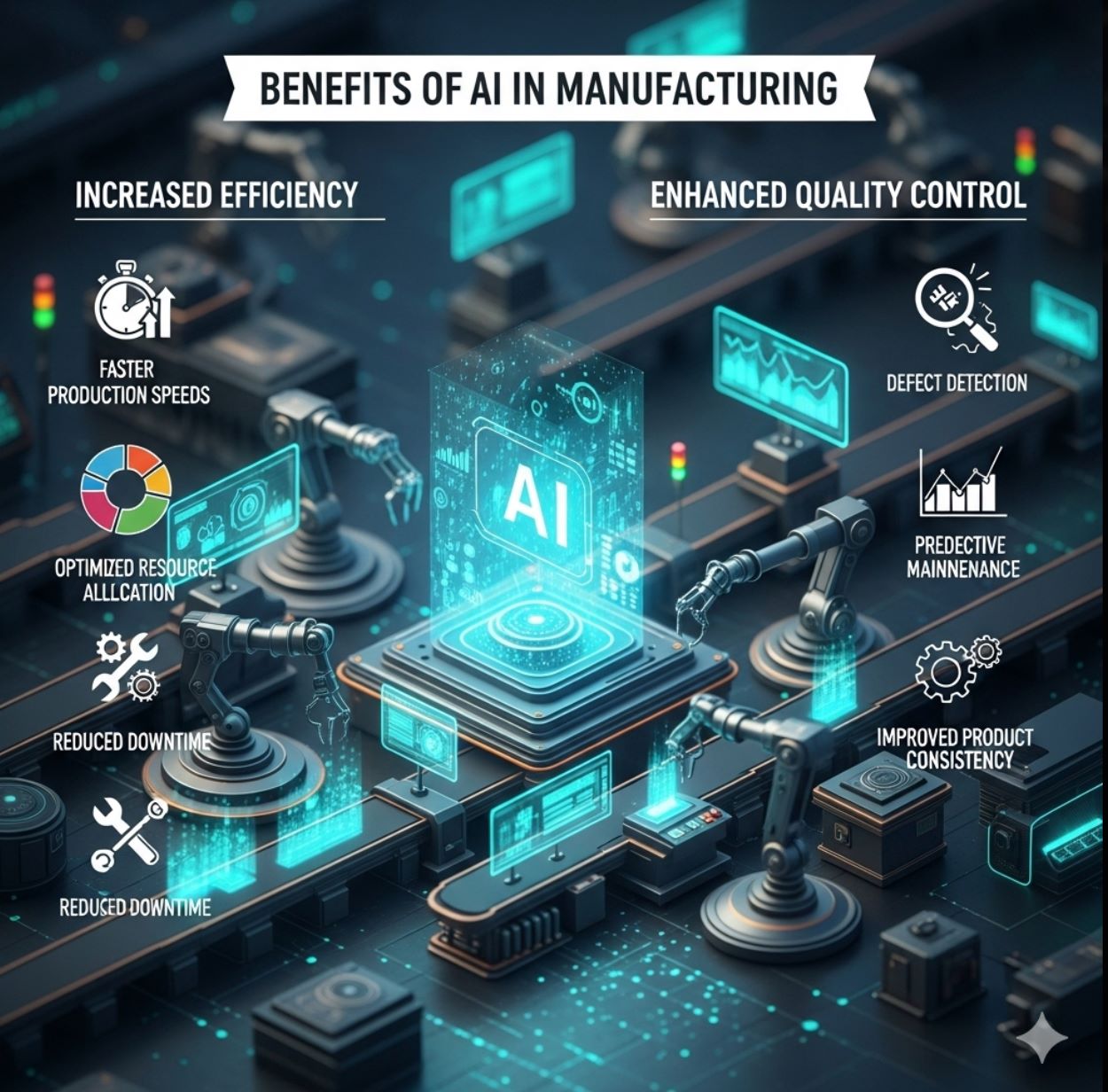

Benefits of AI in Manufacturing

AI delivers multiple advantages across manufacturing operations, transforming traditional factories into intelligent, data-driven enterprises:

Increased Efficiency and Productivity

Reduced Downtime and Costs

Higher Quality and Lower Waste

Faster Innovation Cycles

Enhanced Supply-Chain Planning

Improved Worker Safety

Challenges and Risks

Adopting AI in industry comes with significant hurdles that manufacturers must address strategically:

Data Quality and Integration

AI needs large amounts of clean, relevant data. Manufacturers often have legacy equipment that wasn't designed for data collection, and historical data may be siloed or inconsistent.

- Legacy equipment lacks modern data collection capabilities

- Historical data often siloed or inconsistent

- Many plants lack clean, structured, application-specific data

- Without high-quality data, AI models can be inaccurate

Cybersecurity and Operational Risk

Connecting machines and deploying AI increases exposure to cyber threats. Each new sensor or software system can be an attack surface.

- Increased attack surface with connected devices

- Breaches or malware could cripple production

- Experimental AI models may not be fully reliable in mission-critical settings

- Requires strong security investment and protocols

Skills and Workforce Impacts

There is a shortage of engineers and data scientists who understand both AI and factory operations, creating significant implementation barriers.

- Shortage of AI-savvy manufacturing engineers

- Worker resistance due to job security concerns

- Need for extensive retraining programs

- Clear communication essential for change management

Cost and Standards

Implementing AI requires significant upfront investment and operates in an environment with few established industry standards.

- High costs for sensors, software, and computing infrastructure

- Especially challenging for small manufacturers

- Few industry-wide standards for verifying AI systems

- Lack of frameworks for transparency, fairness, and safety

Key Obstacles

- Legacy equipment integration

- Data quality issues

- Skills shortages

- High implementation costs

- Cybersecurity risks

Strategic Approaches

- Phased implementation with pilots

- Data infrastructure investment

- Workforce training programs

- ROI-focused deployment

- Security-first architecture

Future Trends and Outlook

The trajectory for AI in industry is steep. Experts predict that combining AI with other technologies will reshape factories over the next decade:

Generative AI + Digital Twins

Analysts foresee that fusing generative AI with digital twin models will revolutionize manufacturing, ushering in a new era of design, simulation and real-time predictive analysis.

- Shift from reactive to proactive optimization

- Greatly improved efficiency and sustainability

- Enhanced resilience and adaptability

Industry 5.0 – Human-Centric Manufacturing

Building on Industry 4.0, the EU's Industry 5.0 concept emphasizes sustainability and worker well-being alongside productivity.

- Robots handle heavy, dangerous tasks

- Human creativity remains central

- Circular, resource-efficient practices

- Lifelong learning and digital skills programs

Edge AI and Real-Time Analytics

As 5G and edge computing mature, more AI processing will happen on the factory floor rather than in the cloud.

- Ultra-low-latency control systems

- Real-time quality feedback

- Instant machine adjustments without cloud dependency

Wider Cobot Adoption

Rapid growth of collaborative robots across more sectors beyond automotive and electronics.

- Expansion into food processing and pharmaceuticals

- Accessible for smaller factories

- Increasing intelligence for sophisticated tasks

Advanced Materials and 3D Printing

AI will help design new materials and optimize additive manufacturing for complex parts.

- Localized production capabilities

- On-demand manufacturing

- Reduced supply chain strain

Explainability and Ethics

Manufacturers will invest in explainable AI systems so engineers can trust and verify machine decisions.

- Tools to visualize AI decision-making

- Industry guidelines for safety and fairness

- Transparent, verifiable processes

Studies suggest companies investing early in AI stand to significantly increase market share, revenue and customer satisfaction. While full transformation will take time and careful planning, the direction is clear: AI will power the next generation of smart, sustainable and competitive manufacturing.

— Industry Research Analysis

Top AI Tools in Manufacturing and Industry

Siemens MindSphere

Insights Hub (formerly MindSphere) is Siemens’ cloud-based industrial Internet of Things (IIoT) solution designed to connect industrial assets, collect and contextualize operational data, and generate actionable insights for manufacturing and operational improvements. It enables users and developers to monitor asset health, optimize processes, predict quality issues, and embed custom analytics and dashboards across the enterprise.

IBM Maximo Application Suite

IBM Maximo Application Suite (MAS) is an integrated platform that unifies enterprise asset management (EAM), Internet of Things (IoT) monitoring, AI/analytics, and maintenance optimization under one solution. MAS enables organizations to monitor asset health in real time, predict failures, optimize maintenance schedules, and drive operational efficiency across diverse industries.

Mech-Mind Robotics

Mech-Mind Robotics is a Chinese industrial automation company specializing in integrating 3D vision sensing, AI software, and robotic control to build intelligent robotic systems. Their product suite includes industrial 3D cameras (Mech-Eye), vision & AI algorithm software (Mech-Vision, Mech-DLK), robot programming tools (Mech-Viz), and measurement/inspection software (Mech-MSR). Mech-Mind’s solutions are deployed globally across industries such as logistics, automotive, metal & machining, consumer electronics, and more.

GE Digital

GE Digital’s Asset Performance Management (APM) is a comprehensive software suite designed to help industrial organizations maximize asset reliability, reduce operational risk, and minimize maintenance costs. Built on modular architecture, GE APM enables organizations to deploy individual APM applications or combine them into an integrated enterprise solution. By leveraging advanced analytics, digital twins, and risk-based asset strategies, it supports predictive maintenance and data-driven decision making.

No comments yet. Be the first to comment!